ULTRA PRECISION 5 AXIS CNC MACHINING SERVICES IN CHINA

- Specializes in 5 axis CNC machining services

- Achieve complicated geometries and intricate designs with high precision

- 10+ years experience, 4 facilities & 182 professionals

- Our Fast production assures you always on-time delivery

- Welcome High-Mix, Low volume Projects

Infinite production possibilities with our premium 5-axis CNC machining services.

5 AXIS CNC MACHINING MANUFACTURING FOR ACCURATE COMPONENTS ACROSS A NUMBER OF INDUSTRIES

HOW SUNRISE METAL SUCCEED YOUR 5 AXIS CNC MACHINING PROJECTS

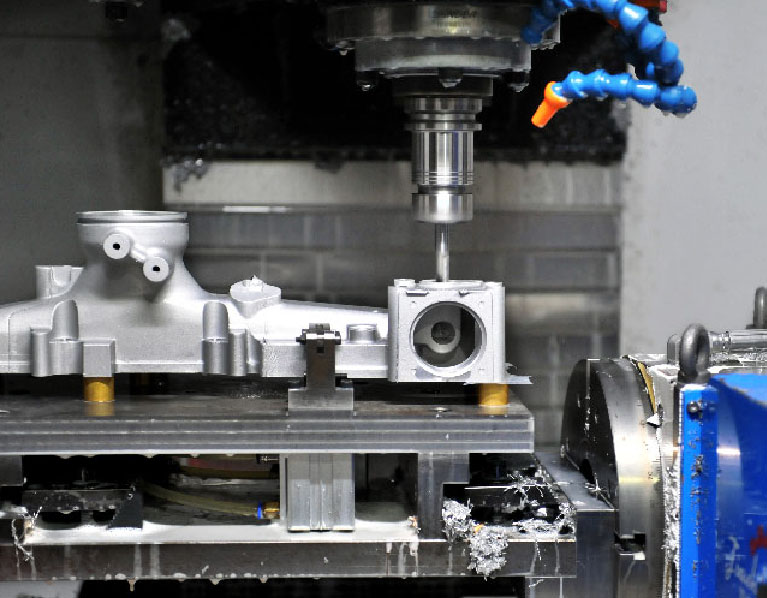

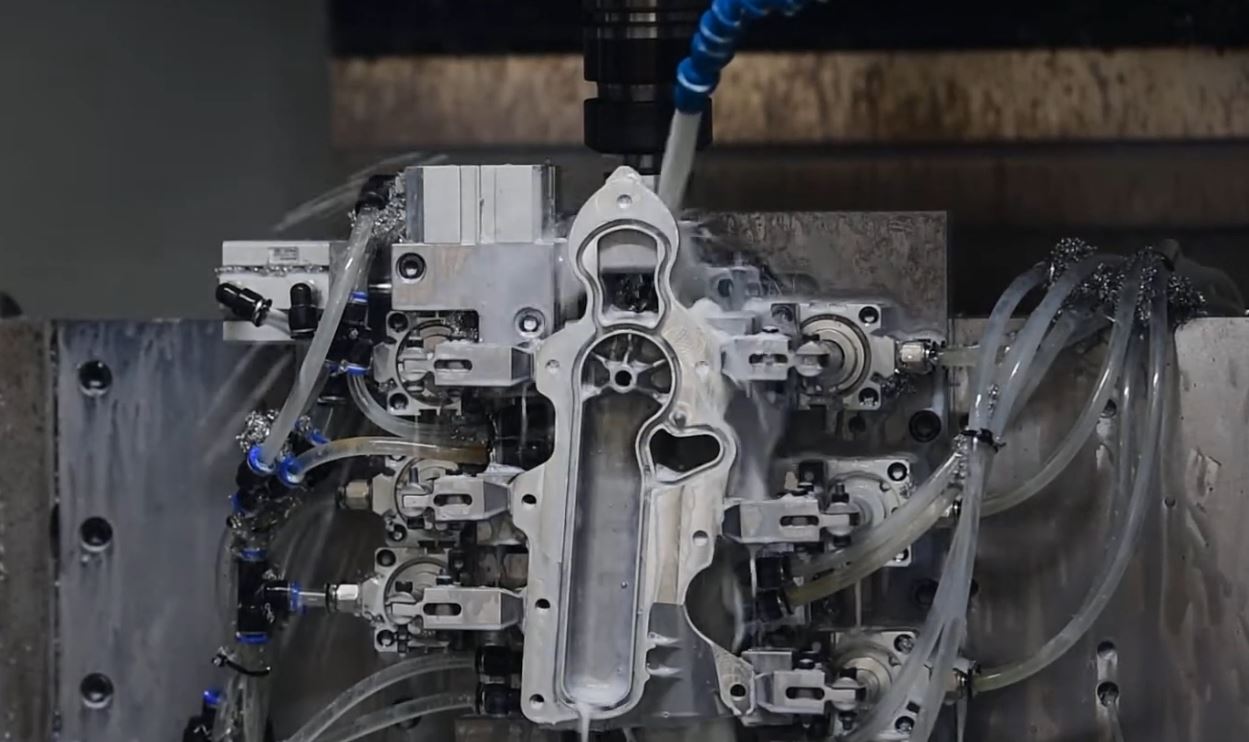

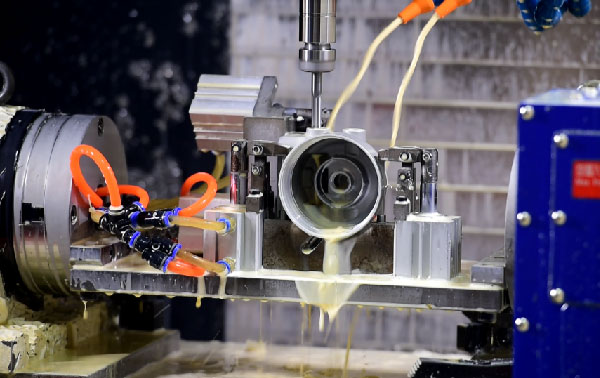

Our 5-axis CNC machining services increase the range of manufacturing of parts. Your required parts with various shapes, sizes, or designs are created with complete accuracy.

With an average of 10 years’ experienced engineering team, we provide you DFM, engineering support during the whole project life.

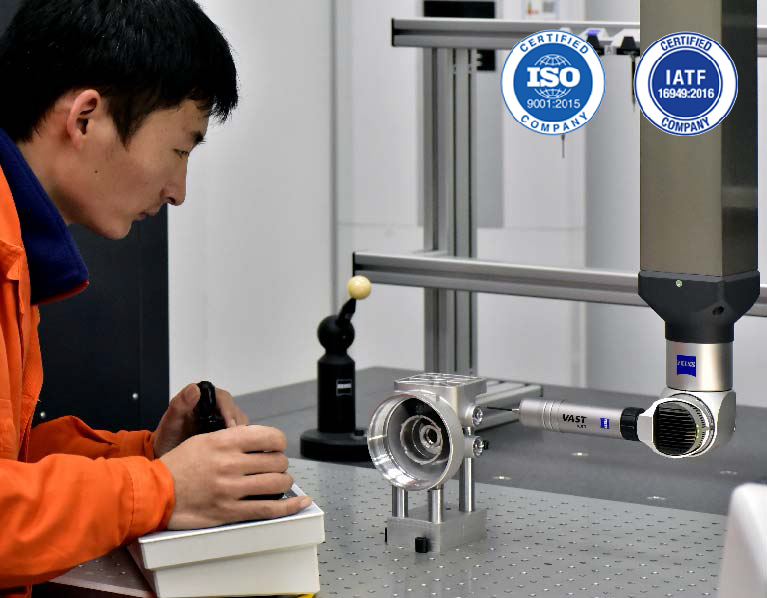

Sunrise Metals is an ISO 9001:2015 and IATF 16949 certified manufacturing company. We work to enhance the quality awareness of all employees. Our remarkable machinists have complete knowledge of the 5 axis machining process.

CNC MACHINING PRODUCTION CAPABILITIES AT SUNRISE METAL EXCEED YOUR EXPECTATIONS

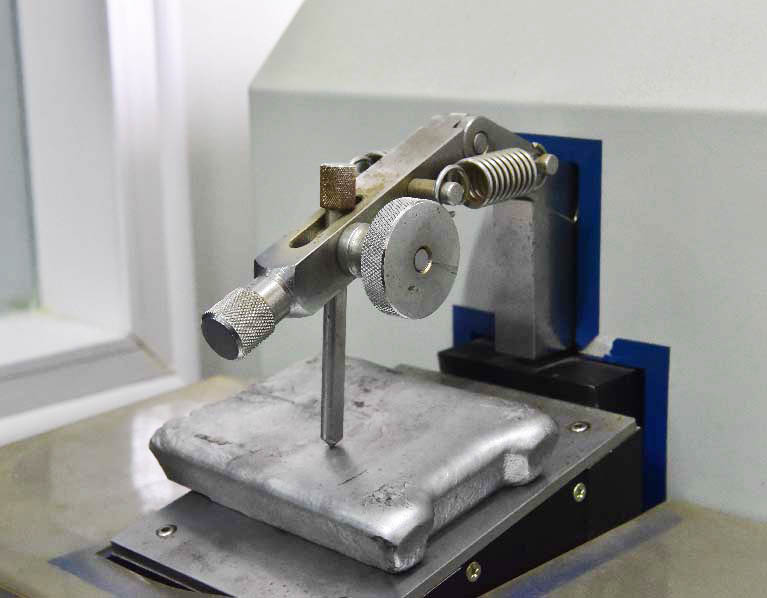

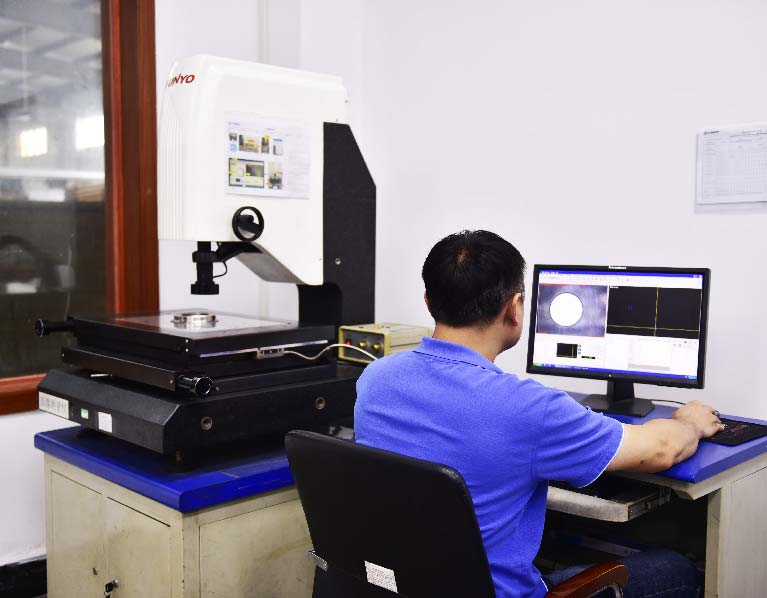

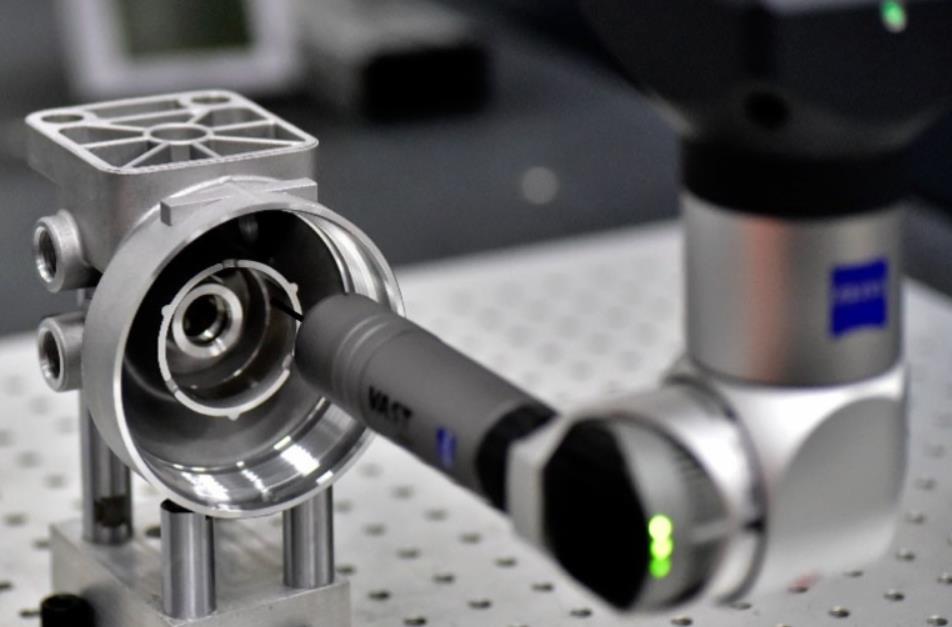

CNC MACHINING QUALITY CONTROL & INSPECTION INSTRUMENTS

Sunrise Metal has been delivering a comprehensive 5-axis CNC machining manufacturing service to our global clients for many years. We keep following an effective quality control system that includes inspection and control at each manufacturing process. That will ensure that all manufactured machined products meet the requirements before reaching the consumer. Here is a full instrument of high precision Carl Zeiss CMM, Spectrum Meters, Projectors, Micrometers, calipers, thread gauges and etc.

- Advanced Equipment

- Premium Quality

Advanced CNC Machining Equipment

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5 axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

GET A FREE A CONSULATION

If you are looking for a 5 axis CNC machining services provider in China, contact Sunrise Metal. When you have any hesitation or any design doubt on your 5 axis CNC machining projects, Sunrise Metal Engineering Team can be your free consulter. Sunrise Metal gives suggestions on your CNC machined parts at 3 aspects:

1. Your design evaluation.

2. Feasibility analysis for mass production.

3. Project time and part’s cost-saving.

Contact us now, to see how we can help you with your CNC machined projects.

Here is just a small part but an important way that we’re serving you on 5 axis CNC machining projects.

Sunrise Metal can offer full chain service if you have any needs on aluminum die casting projects. Looking learn more about aluminum die casting.

5 AXIS CNC MACHINING SERVICES:

THE ULTIMATE FAQ GUIDE

5 Axis CNC Machines are one of the most advanced CNC equipment available in China. Due to its versatility and precision, it can be used to carry out almost any machining operation at hand. So, it is preferable for manufacturing complex parts with ease.

Sunrise Metal can offer you top-notch 5 Axis CNC Machining services. You can count on us for excellent quality and competitive pricing for your project. This guide will inform you about fundamental things you need to know about 5 Axis CNC Machining and how we can help you with it.

- What is 5 Axis CNC Machining?

- How Does 5 Axis Machining Work?

- What are the Different Varieties of 5 Axis CNC Machines Available in China?

- What are the advantages of 5 Axis CNC Machining Services?

- How accurate is 5 Axis CNC Machining?

- Is 5 Axis CNC Machining Expensive?

- When is 5 Axis CNC Machining Service a Viable Option?

- What Materials are Used in 5 Axis CNC Machining?

- What are the Applications of 5 Axis CNC Machining in Different Industries?

- What is the Difference between 5 Axis and 3+2 Axis CNC Machining?

- How Sunrise Metal control quality on 5 Axis CNC Machining?

- What is the Difference Among 3, 4, and 5 Axis CNC Machining?

- What are the 5 Axis CNC Machines Available at Sunrise Metal?

- What Measuring Devices can be used to ensure the precision of 5 Axis CNC Machining?

- Can I See Some of the 5 Axis CNC Machining Projects Completed by Sunrise Metal?

- What parts can be made by 5 Axis CNC Machining?

- Does 5 Axis CNC Machining Service Suit for Custom and Low Volume Production?

What is 5 Axis CNC Machining?

CNC Machining is a computerized process of cutting solid blocks to create a part. 5 Axis CNC machining is something that allows simultaneous movement along 5 axes during this machining process. It grants greater flexibility to the manufacturer.

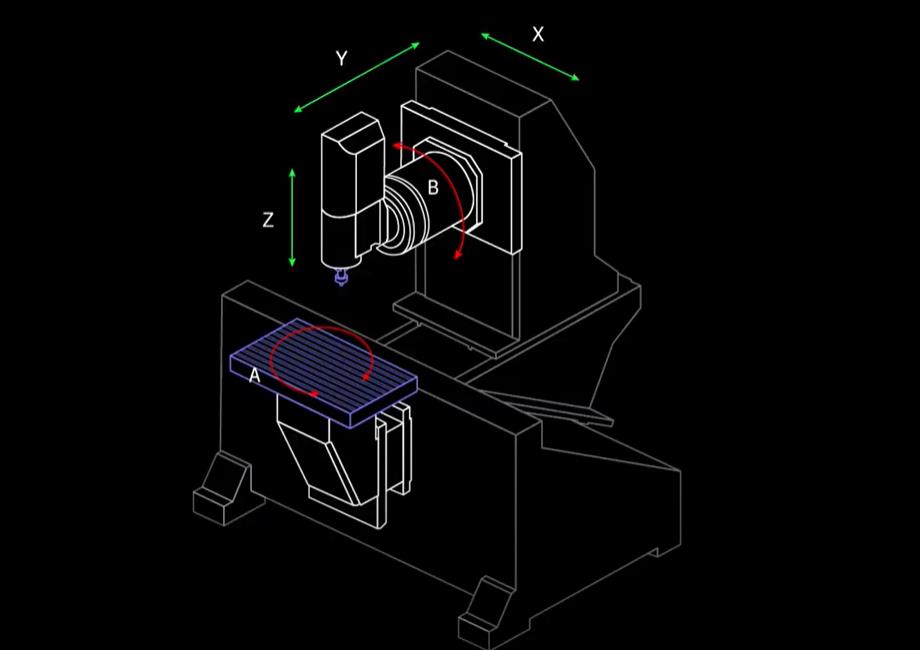

Typically, we mostly come around a 3 Axis CNC Machine that only allows movement of the tool along 3 axes while the table holding the part is kept stationary. But, a 5 Axis machine allows movement of both the tool and table.

The tool of a 5 Axis machine can move horizontally along the X, Y-axis, and vertically along the Z-Axis. What’s interesting is that the table is also capable of rotating along two more additional axes called the A and B-Axis.

Usually, A denotes rotation about the machine’s X-Axis, and B denotes rotation about the machine’s Y-Axis. You may also come across 5 Axis machines where the two additional axes are referred to as A and C, or B and C as well. C just means that the rotation takes place about the Z-Axis.

The Multi-axis movement enables manufacturers to deal with a complex project without having to worry about changing the setup multiple times. So, 5 Axis CNC Machining services can significantly minimize the manufacturing difficulty.

How Does 5 Axis Machining Work?

There are three major steps in the 5 Axis CNC Machining Process. It involves,

- Creating a CAD Model

- Programming with a CAM Software

- Running the Code in the 5 Axis CNC Machine

I have briefly explained the following processes below.

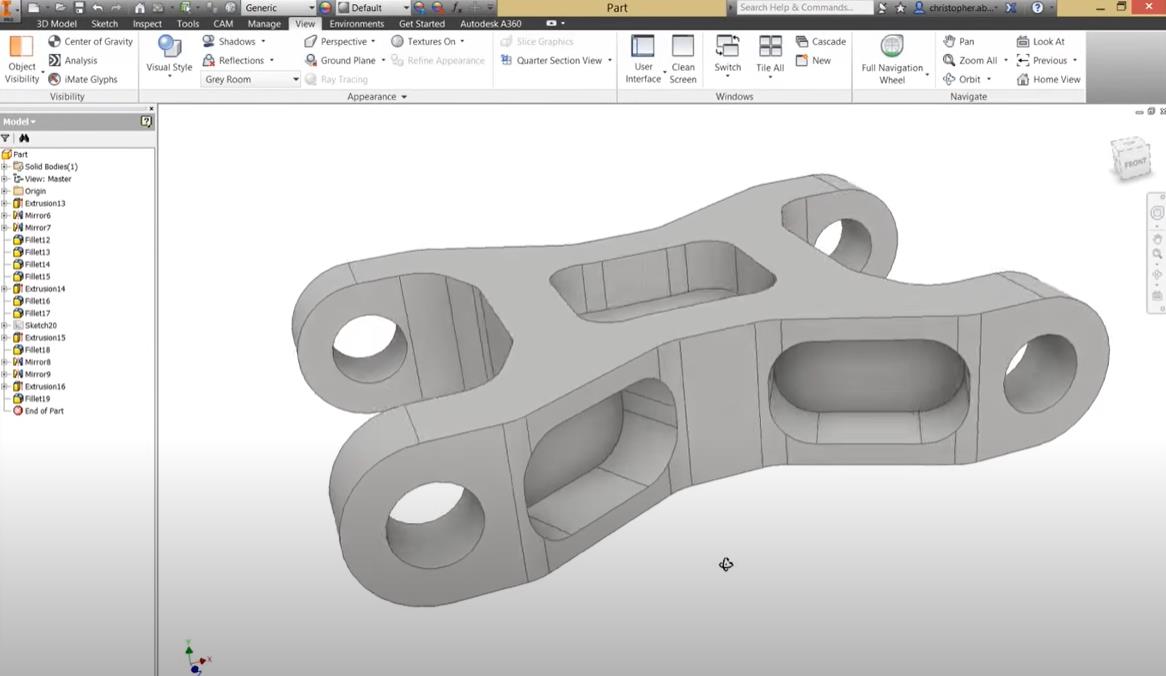

CAD Modeling

The prerequisite to any manufacturing is making a model of your desired item. There is many CAD software available that you can use to create 3d models for your project. Modeling your parts is relatively easy compared to other tasks.

But, it’s more about how you model parts. You may be very good with CAD software. But extensive knowledge and experience are required if you want to do it more efficiently. Because even some minor details can complicate the machining process.

It can lead to delays and increase manufacturing costs. But, when it comes to 5 Axis CNC Machining, you have way more flexibility in how you model your parts. So, you can design more complex parts without worrying about production difficulty.

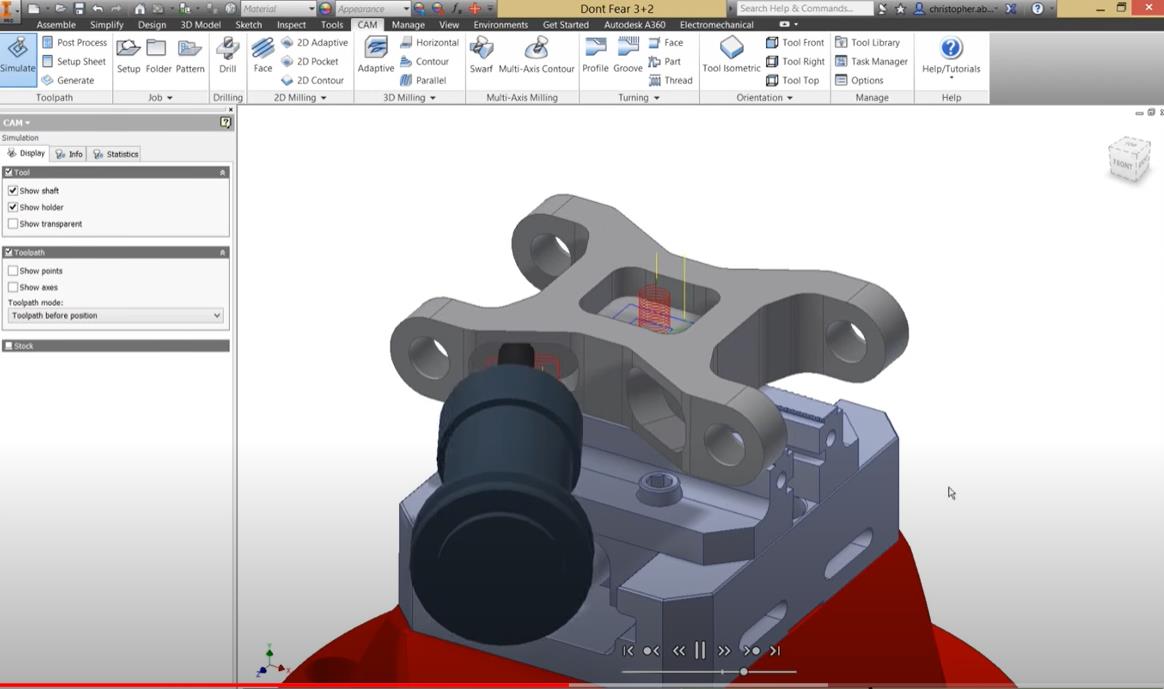

CAM Programming

Once you are done with modeling your parts, next is programming. Because CNC machines cannot directly execute a CAD model. You need to create a proper set of instructions for the 5 Axis CNC Machine using CAM software.

CAM software is a program that can generate an ideal toolpath for the machining process. These paths are stored in the form of a code called G-Code. You can also simulate the whole machining process with the CAM software.

Simulation is necessary to ensure the accuracy of your programming. Because even a slight error can cause the machine to crash. You can also find out alternative ways to machine a part through simulation that would be more efficient.

Running CNC Machine

Finally, the instructions/codes generated by the CAM program is fed into the 5 Axis CNC Machine. A suitable block of material is placed into the machine and calibrated with the help of some tools to confirm the placement.

Then the machine operator can start the machining operation. The rest of the process is fully automated without any need for tools or setup changes. The machine can move the tools and rotate the workpiece to a suitable angle to reach any recesses of the part.

Here’s a video that explains the 5 Axis CNC Machining process from scratch.

What are the Different Varieties of 5 Axis CNC Machines Available in China?

5 Axis CNC Machine is a type of CNC Machine that has freedom of movement along 5 directions. But depending on the build of the machine it can be further classified into two categories.

- 3+2 Axis CNC Machine

- Simultaneous 5 Axis CNC Machine

Details about these two types of 5 Axis machine is shared below.

3+2 Axis CNC Machine

The 3+2 Axis CNC Machining is basically a 3 Axis CNC Machine with the additional rotational capability of the table. The tool function just like a 3 Axis machine would do. But the table can rotate along two other Axis to allow machining at other angles without changing the setup or orientation of the parts manually.

But the table and tool movement doesn’t take place simultaneously. Whether the tool or table moves, one will remain stationary when the other is moving along any axis.

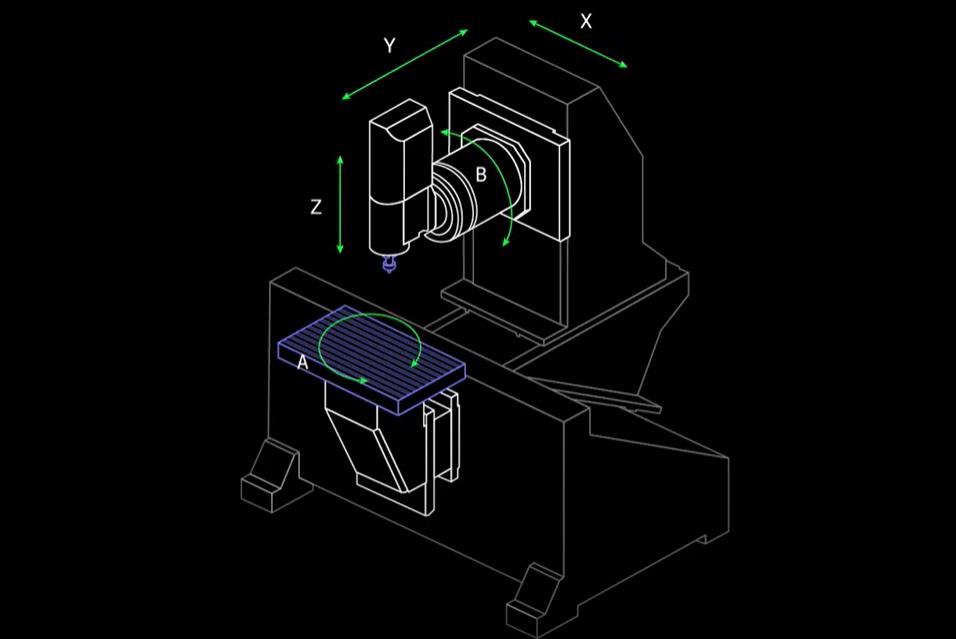

Simultaneous 5 Axis CNC Machine

Simultaneous or Full 5 Axis CNC Machines allow movement of the tool and table at the same time. So, the workflow is much faster due to the coordinated movement of the tools and table. It is also capable of creating more complex parts.

Operating a simultaneous 5 Axis CNC Machine requires expert machinists with extensive programming knowledge and experience. So, new machining shops may face some difficulties dealing with a full-blown 5 Axis CNC Machines.

What are the advantages of 5 Axis CNC Machining Services?

5 Axis CNC Machines services can offer you lucrative advantages that will make you want to go for it. The capabilities of it can open new windows of opportunity for your project and boost your production. Here are some facts about how you can benefit from 5 Axis CNC Machining services.

Create Complex Parts

5 Axis CNC Machining can introduce more complex features in your parts. Some complex geometric features such as arcs, and undercuts can be hard to achieve with a regular CNC Machine. 5 Axis machines can handle these very easily.

Shorter Lead Time

It is capable of rotating the workpiece during machining. So, you don’t have to waste any time dealing with changing the setup or orientation of the workpiece. You are also relieved from the trouble of re-calibrating the workpiece positions every time you change the setup.

Accuracy is Ensured

Having to change the setup frequently will disrupt your workflow and accuracy. When the setup is changed the workpiece must be placed very carefully. Even a slight error during placement can compromise the accuracy of your parts. 5 Axis machines can easily overcome this issue.

Little to No Chance of Errors

Manual setup changes always carry the risk of errors unless strictly supervised. You don’t have to worry about these with 5 Axis CNC machining. And the chances of errors during machining is also highly unlikely.

Labor Requirement is Less

5 Axis CNC machining is a complete manufacturing solution itself. It drastically reduces the handling operations thus reducing the need for laborers. So, some projects may prove 5 Axis machining to be more economical and efficient.

How accurate is 5 Axis CNC Machining?

5 Axis CNC Machining is significantly more accurate than the older generation machining processes. Due to its ability to complete a machining process with a single setup, there is less room for errors.

So, parts manufactured through 5 Axis machining generally yields more precise parts. Although the extent of precision can often vary due to the capability of a 5 Axis machine and the programming of the machine.

Sunrise metal’s 5 Axis CNC machining service is one of the finest in China. We can offer ultra-precise parts with tolerances up to 0.005 mm (0.0002 inches). Our expert designers and programmers ensure maximum efficiency and error-free machining process for the best results.

Is 5 Axis CNC Machining Expensive?

5 Axis CNC Machining is generally more expensive than traditional machining approaches. That’s nothing to be surprised about. Because it is normal that more advanced technology will cost more. So, why should you prefer 5 Axis CNC Machines despite the cost?

It all boils down to your product quality and production time. In terms of capabilities and efficiency, 5 Axis CNC Machines are far more superior to the older machines. The machine itself is pretty expensive but the whole process is not.

Your production cost is not dependent on the cost of the machine alone. There are several other factors such as material cost, labor, lead time of your project. 5 Axis machines have little room for error which reduces production wastage.

The labor requirement is also minimized in this case. The rotational movement allows faster machining without any tool change. All these factors drastically reduce some production costs and time. So, you get a faster return on your investment.

So, 5 Axis CNC Machining is not as expensive as you think. The benefits eventually outweigh the extra cost in most of the case. Plus, several geometries are not possible or very hard to manufacture with regular machining.

When is 5 Axis CNC Machining Service a Viable Option?

You must take into consideration various factors before you can decide a suitable manufacturing technique for your parts. The material, precision requirement, budget, surface quality, lead time, etc. should be the major deciding factors.

When we are talking about any CNC machining process, we are also talking about precision. Any CNC machining can provide you excellent precision. But among different types of CNC machines, 5 Axis machines offer the highest level of accuracy by omitting the need for setup changes.

So, when you are looking for a reliable option, 5 Axis CNC machining is the way to go. 5 Axis CNC Machines are also significantly faster than a 3 or 4 Axis machine. Because there is no time lag due to frequent tool and setup changes. It will provide the fastest solution for your project.

Now, the most important thing is your probably the complexity of your part. If your part has relatively simple geometry and requires minimal setup changes, then you are better off with 3 Axis machining.

A major advantage of 5 Axis CNC Machining is the ability to create complex parts with ease. But if you make parts that can be easily machined in a 3 Axis machine, then you will only raise your production cost without any significant gain.

But with more technological advances in the manufacturing industry, the cost of 5 Axis CNC Machining will hopefully become more affordable. Then 5 Axis machines will become more preferable for regular projects very soon.

What Materials are Used in 5 Axis CNC Machining?

5 Axis CNC machining is a versatile process that can be done on different types of metals, plastics, or even on woods. Both small and large types of parts can be machined on almost all materials.

Here are some of the common materials that can be machined with a 5 Axis CNC machining parts can be done seamlessly

Aluminum

It is the most and widely varied material when it comes to CNC machining. There are different types of aluminum available in the market like Al6061, Al6063, Al5052, Al7075, etc. they have great corrosion resistance and have higher fatigue strength.

It is lightweight but got a good strength level. Electronic hardware, aircrafts components, automotive components, and other types of components heavily rely on Aluminum and CNC machining job.

Steel

Steel is an excellent choice for 5 Axis CNC machining. It offers excellent machinability and high strength. They can be heat treated to relieve any machining stress and further increase the strength properties.

Brass

Brass is another metal that can be machined into a 5 Axis CNC machine. It also has got good corrosion resistance and resilient to other metals. These are also used to make electronic parts and other stuff.

Copper

It is a good choice of machining material if the parts have an application in electrical equipment. It has exceptional electrical conductivity. But offers less protection as it is weak against acids and other few chemical solutions.

Plastics

Plastic is an excellent material to perform 5 Axis CNC machining as it has got good impact strength and brilliant machinability. Plastics have numerous uses like medical devices, pipes, and other essential things.

The materials mentioned above may be alloyed with other elements to enhance the material properties thus making that a viable option for 5 Axis CNC machining.

What are the Applications of 5 Axis CNC Machining in Different Industries?

CNC machining is a booming sector in different industries. 5-axis CNC machining has superior capabilities and has many significant applications in numerous industries. A few of its applications are given below.

Automotive

The automotive sector is an important one that uses 5-axis CNC machining tools to get high quality and top-notch products. As we all know that automotive sectors need precise components with high tolerance, for what CNC machining is a trustworthy option for them.

Aerospace

The aerospace sector demands high precision parts with complex geometry. A 5-axis CNC machine can help greatly to fulfill all these requirements. It can ensure proper geometric, exact components, and higher accuracy.

Energy

The energy industry also uses the 5-axis machining tool for high-quality components with tight tolerances. As the energy industry mainly works in an extreme environment and also deals with hazardous situations, for what they need precise and critical components.

Marine

Marine is also a good sector that deals with 5-axis machining. Most marine vehicle turbines and engine housings are prototyped or manufacturer using 5 Axis CNC Machining. CNC machining can provide corrosion-resistant products with extended durability.

Medical

The medical sector has good demand for 5 Axis CNC machined precision parts. For obtaining components with extreme precision, 5 Axis CNC machining is a reliable tool. Precision parts can be produced faster with shorter lead times.

Apart from all these sectors, there are many other applications for 5 Axis CNC machining in China and around the globe.

What is the Difference between 5 Axis and 3+2 Axis CNC Machining?

Both of these processes are technically 5 Axis CNC Machining. Because there are five axes of freedom in both cases. But, when it comes to capabilities, full 5 Axis CNC machining is more superior to 3+2 Axis CNC machining.

The fundamental difference between these two types of machines lies in their functionality. The 3+2 Axis CNC Machine is basically an extended version of the 3 Axis CNC machine. The main difference is two additional axes of rotation for the table.

The workpiece can be simply rotated instead of manually changing the orientation of the parts. But a disadvantage is that the table and tools don’t move simultaneously. While the table changes the workpiece orientation, the tool remains fixed in the three principal axes.

So, 3+2 Axis CNC Machines have some limitations and certain geometric features would be hard to achieve with it. But it provides a more affordable solution than simultaneous/full 5 Axis CNC Machining.

On the other hand, full 5 Axis machines are way more versatile but relatively costlier than 3+2 Axis machines. It can simultaneously control the movement of the table and tools at the same time. So, more difficult geometry can be dealt with easily.

It is especially beneficial for introducing complex arc shapes and undercuts in parts. It can easily reach any recesses of the part. The simultaneous movement also reduces the overall machining time.

How Sunrise Metal control quality on 5 Axis CNC Machining?

Sunrise Metal prides upon its superior quality management system. Our strict quality control measures are aimed to deliver your parts with maximum quality. The following facts should help you better understand our quality control over the 5 Axis CNC Machining services.

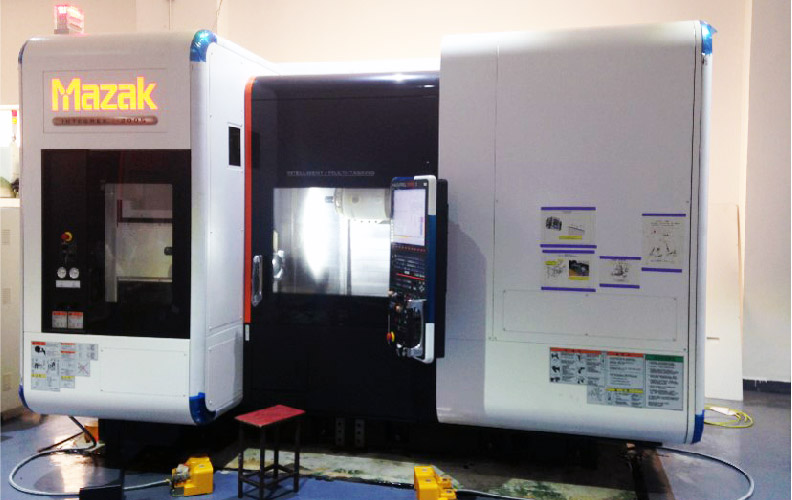

Advanced 5 Axis Equipment

Sunrise Metal has in-house 5 Axis equipment from renowned brands like Mazak and Hass. The machines are built with the latest technology and capable of handling complex machining jobs with excellent precision.

International Certification for QC

We have achieved international recognition for the quality management system. We are certified for our CNC machining quality management by the IS9001. Our automotive parts manufacturing facility is certified by the IATF 16494 for superior quality control.

High Precision Measuring Device

Our labs are equipped with high precision Coordinate Measuring Machines (CMM). They can measure the accuracy of your parts with an extreme level of precision. So, you can rest easy about the precision of your manufactured parts.

Organized Quality Management System

Our coordinated quality management system is capable of efficiently dealing with the quality control of your project. We have a dedicated quality control team of experts for the quality control of your project.

What is the Difference Among 3, 4, and 5 Axis CNC Machining?

The basic principle of all CNC machining processes is quite similar. But still, there are some significant and unique differences among 3, 4, and 5 Axis CNC machining that makes one more suitable than the other for a certain task.

A 3 Axis machining is the traditional CNC machine tool that can operate on the X, Y, and Z-axis. In this machining process, the workpiece remains stationed and the cutting tool moves as per the design and cuts the mold.

3 Axis machining has some limitations to the cutting process as it can not rotate or spin like other 4 or 5-axis machining tools. The workpiece has to be manually adjusted to enable machining details from different angles.

On the other hand, the 4 Axis machine tool has got an additional axis called the A-axis. Like a traditional 3 Axis CNC machine tool, 4 Axis has got X, Y, and Z-Axis too. But the workpiece can rotate along an additional A-Axis to allow machining from different angles without setup changes.

The 5 Axis machine is the most advance among all other CNC machining equipment. It has two additional rotational axes apart from the X, Y, and Z-Axis of a traditional 3-axis CNC machine. The additional axes are usually denoted by A and B Axis.

5 Axis machines are capable of handling more complex design and shape compared to 3 and 4 Axis machines. Also, 3 and 4-axis CNC tools can not perform undercut design so easily like a 5-axis CNC machining tool which can do it on a single machining setup.

All in all, 5 Axis machining offers better quality and surface finishing for your parts. Due to its single setup functionality, it is much faster compared to 3 and 4 Axis CNC machining.

Here is a video that explains the fundamental differences between these different types of machining processes.

What are the 5 Axis CNC Machines Available at Sunrise Metal?

Sunrise Metal has four in-house 5 Axis CNC machines. The equipment is manufactured by Mazak Corporation and Hass Automation Inc. They are the leading machine tool manufacturer around the globe right now.

The stroke of the Mazak 5 Axis CNC Machine is Ø800. It is capable of multiple-surface machining and simultaneous five-axis operation. It can store about 30 tools and has an optional two pallet changer. So, it is fully automated and capable of running unattended for long periods.

The Hass 5 Axis CNC Machines are Ø600 stroke equipment with 40 tapers and about 30 tool capacity. The functionality is quite similar to the Mazak CNC machine. Both of the equipment can handle sophisticated machining tasks.

So, you can rest assured about our 5 Axis CNC machining capabilities. Our superior core competence will ensure that you get the best quality parts from us.

What Measuring Devices can be used to ensure the precision of 5 Axis CNC Machining?

The precision of 5 Axis CNC machined parts can be measured using a Coordinate Measuring Machine (CMM). It is a device that can measure the geometric aspects of a part by sensing some specified points of using a probe.

Different types of CMMs are classified based on the type of probe used for measuring. The most common probes used are optical, mechanical, laser, etc. Each probe has a different scale of accuracy.

CMMs can be both manual or hand-operated. It usually allows movement along the three principal axes X, Y, and Z. Some CMM machines support angular movement too, which enables measuring more complex details.

Sunrise Metal uses the latest technology CMM by Carl Zeiss to ensure optimum precision of our 5 Axis CNC machined parts. It is equipped with an automatic scanning feature taking repeated measurements.

With the Zeiss CMM, we can measure the accuracy of your parts with a precision of up to 0.001mm (0.00004 inches). Such a high level of precision allows us to check the surface finishing depth of your parts as well.

Here is a video of one of our employees checking the parts’ precision with a CMM.

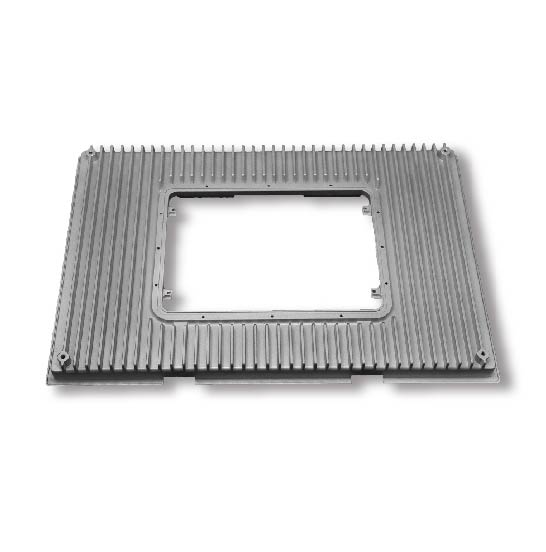

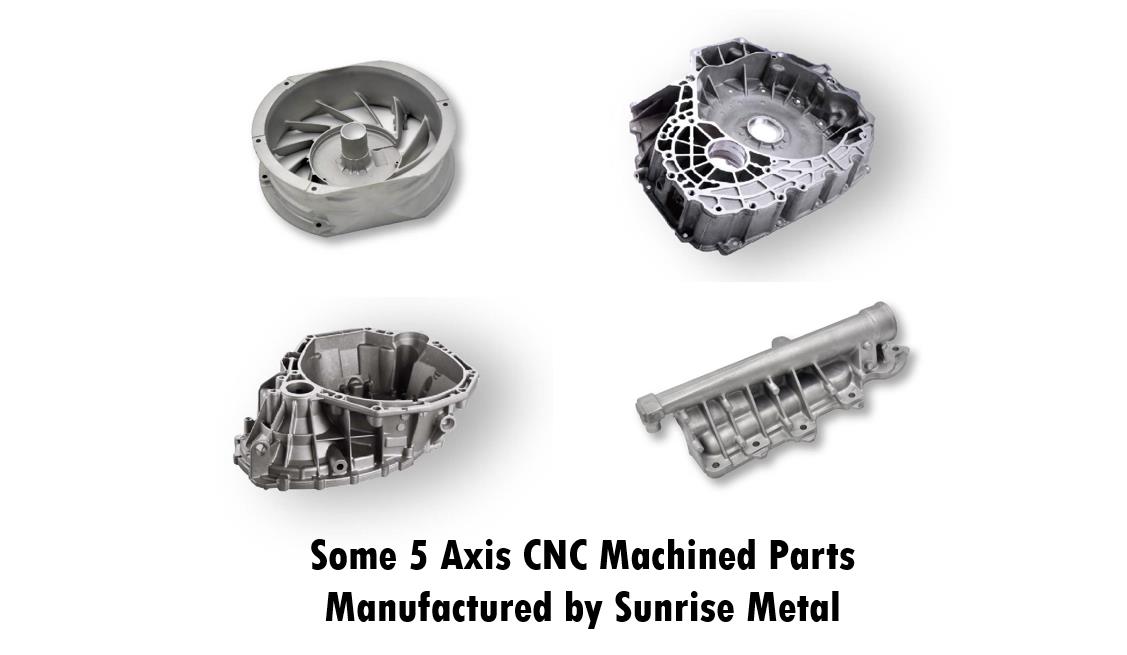

Can I See Some of the 5 Axis CNC Machining Projects Completed by Sunrise Metal?

Sunrise Metal has completed numerous 5 Axis CNC Machining projects for the clients. We are experienced in making sophisticated parts with 5 Axis machining for many industries such as the Automotive, Medical, Marine, Telecommunication, etc.

Some of our notable 5 Axis machining works are shown below.

What parts can be made by 5 Axis CNC Machining?

5 Axis CNC machining is mainly preferred for manufacturing parts with a complex geometry that is hard to machine using regular CNC equipment. So, many industries opt to 5 Axis CNC machining services to meet their demand for high precision parts.

There is a wide range of applicability for 5 Axis machined parts in many industries of China. It has become a very popular approach to making automotive parts. Complex parts such as Engine Housing, Engine-Filter Housing, Intake Tube, etc. can be manufactured with high accuracy.

Complex bracket design for medical devices also became easy now. 5 Axis machines can efficiently create complex housing and turbines for marine vehicles. Complex turbine designs are often impossible to execute without 5 Axis machining.

Does 5 Axis CNC Machining Service Suit for Custom and Low Volume Production?

5 Axis CNC machining service is definitely suitable for any custom and low volume production. In fact, 5 Axis manufacturing is rarely preferred for large volume production. Because the large volume production cost can be pretty intimidating for most companies.

5 Axis CNC machining is heavily used in the Chinese industries for making functional prototypes with intricate details. It is also a viable solution for rapid tooling and die casting molds within a very short time frame.

Many businesses prefer 5 Axis machining for custom and low volume production. It is often a more cost-effective solution than going through the long process of designing, prototyping, tooling, and die casting the final product.

So, production time for low volume projects can be greatly minimized and you can get an early return on your investment. This crucial for many OEM/ODMs and startups that have a limited manufacturing demand.