Your Fantastic Prototype CNC machining Manufacturer in China

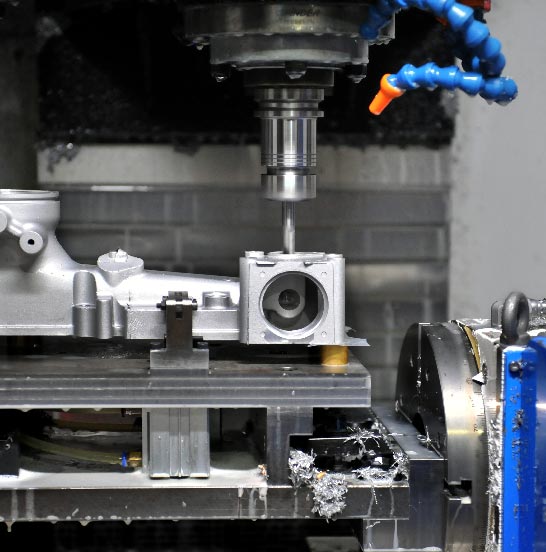

With the advanced producing equipment, such as 5 Axis CNC Machines & 7 axis CNC Machines, and our well-trained engineering team, Sunrise can produce the most complex prototyping CNC machining parts for you. Sunrise Metal, with more than 10 years of experience, is an absolute manufacturer for your prototype CNC machining projects.

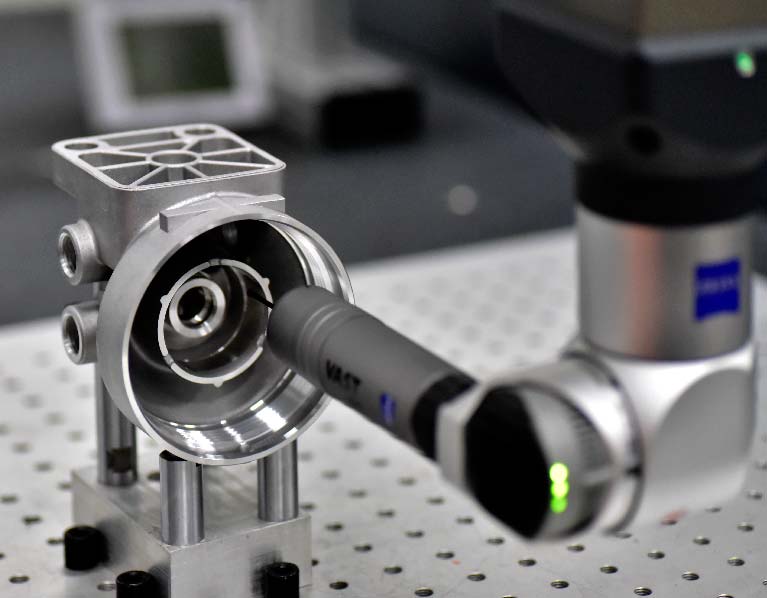

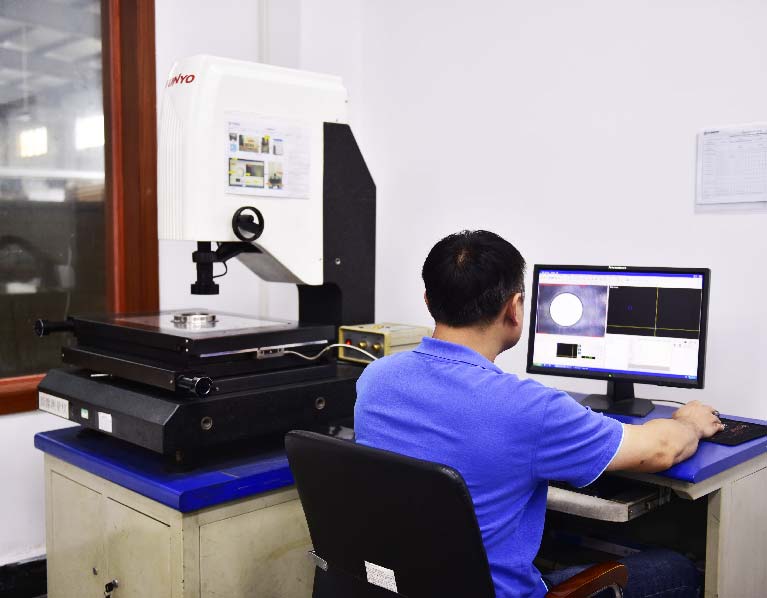

Sunrise Metal’s highly skilled QC team, supported with our advanced Carl Zeiss CMM, X-ray detector, spectrometer, and other inspection instruments, we can assure all aspects of your prototype’s quality.

Time to prototype metal parts is extremely important,

Sunrise Metal develops a fast production system. 1~200pcs parts can be delivered in 1~2 weeks.

You Can Rely on Sunrise Metal for Your Prototype CNC Machining Parts

Sunrise Metal's Full Series Prototype CNC Machining Service Offer You Added Value

Sunrise has a machining workshop equipped with a variety size of machines, which allows to do a wide range complex of machining work and provide our customers with strongest period.

Sunrise, as a professional Prototype CNC Machining service provider, mainly focus on the projects of high precision and complex geometry.

We are dedicated to low to medium volume projects. With our own Prototype machining center, we can reach on-time delivery for a normal order.

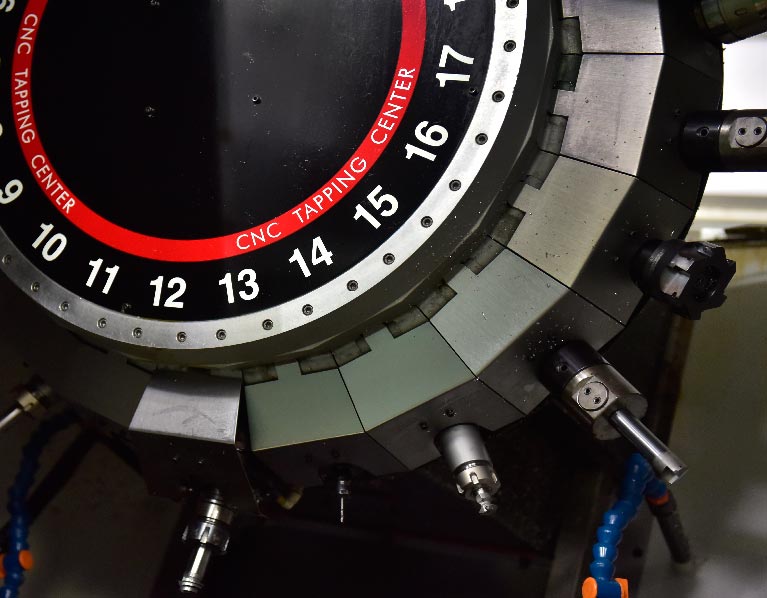

Your Excellent Prototype CNC Machining Parts Coming From Sunrise High End Manufacturing Equipment

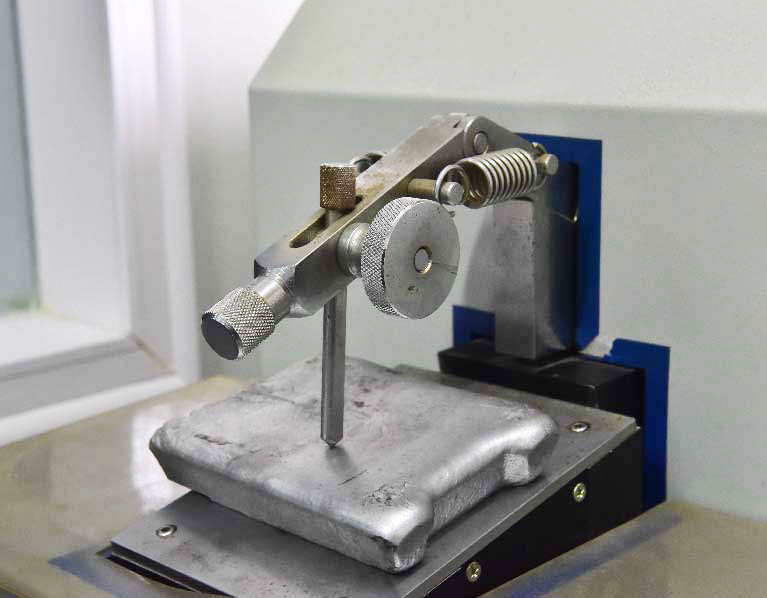

Sunrise High Precision Measuring Instrutments Guarantee The Quality Of Your Porototype Machined Parts

Sunrise Metal is ISO9001 & IATF 16949 certified company. We possess full sets of high precision measuring instruments, including Spectrum Meter, X-Ray Detector, Carls Zeiss CMM, etc. Our rich experienced quality staff and strict quality control can assure the quality of your prototype CNC machining projects. Sunrise Metal’s Quality control is assured for you.

- Experienced Team

- Advanced Equipment

- Global Clients

- Premium Quality

- Fast Delivery

Sunrise Metal has a dynamic workforce including organized teams of experienced engineers, professional customer service representatives, quality assurance officers and skilled production workers. Following international guidelines on cooperation and production standards, they make the best team for your projects.

| No. | Name | Stroke | Q’ty |

| 1 | Mazak 7-axis turning&milling Machine | Ø658*1011MM | 1 |

| 2 | Mazak /Hass 5axis CNC machine | Ø850/Ø600 | 4 |

| 3 | 3-axis CNC machine center | 2000*1500MM | 1 |

| 4 | 4-axis CNC machine center | Ø250*800MM | 8 |

| 5 | 3-axis CNC machine center | 1000*600*600MM | 20 |

| 6 | CNC Lathes | Ø320*800/Ø610*1000MM | 2 |

| 7 | Sodick Wire cutting Machine | 400*400*200MM | 3 |

| 8 | EDM machine | 500*400*400MM | 2 |

| 9 | Surface grinder | 600*300*200MM | 1 |

| No. | Name | Brand | Q’ty |

| 1 | CMM | Carl Zessis | 1 |

| 2 | CMM | SanYou | 1 |

| 3 | Spectrometer | China | 1 |

| 4 | Microscope | China | 1 |

| 5 | Projector | China | 2 |

| 6 | X-ray Detector | SANDT | 1 |

| 7 | Cleanliness Test Equipment | China | 1 |

| 8 | Leakage Test Equipment | China | 2 |

| 9 | Salt Spray Testing Equipment | China | 1 |

| 10 | Pneumatic Measuring Instrument | China | 2 |

| 11 | Hardness Testing Machine | China | 1 |

| 12 | Color Meter Machine | China | 1 |

| 13 | Thickness Testing Machine | China | 1 |

| 14 | Electronic Balance | China | 1 |

| 15 | Density Balance | China | 1 |

Get A Free Consultation

Please send your CAD & Step drawings and project information to sales@sunrise-metal.com. Our skillful engineering consultants will get suggestions to you within one working day.

Here is just a small part but an important way that we’re serving you on prototype CNC machining projects.

Sunrise Metal can offer full chain service if you have any needs for aluminum die casting. Looking learn more about aluminum die casting.

PROTOTYPE CNC MACHINING- THE COMPLETE FAQ GUIDE

Prototype CNC Machining is considered a quick, precise, and versatile solution.

Prototype CNC Machining is a subtractive and an exceptional prototyping process where raw or unwanted material is removed with a majority of precision cutting tools in regards to making a final product.

Furthermore, this cutting through the tool is done through AI (artificial intelligence).

However, advanced and accurate expert software is used to control the equipment/tool based on the 3D design/prototype.

We are the best in this work because our team of engineers programs the equipment/tool to optimize the cutting time, surface finish, and final tolerance to meet your specifications perfectly.

- What is Prototype CNC Machining?

- What is the process of Prototype CNC Machining?

- What are the reasons to use Prototype CNC Machining?

- How is CNC Machining beneficial for Prototyping?

- What are the advantages of using Prototype CNC Machining?

- What are the Milled parts in Prototype CNC Machining?

- What are the Turned parts in Prototype CNC Machining?

- What are the applications of Prototype CNC Machining?

- How Prototype CNC Machining design precision machining parts?

- What are the materials & finishes required by the Prototype CNC Machining?

- How to determine which surface finish is required by which CNC machined prototype?

- Why prefer Prototype CNC Machining?

- Can you get tight tolerance parts from Prototype CNC Machining?

- What are the threaded options for Prototype CNC Machining?

- What benefits Prototype CNC Machining offers?

What is Prototype CNC Machining?

CNC represents Computer Numerical Control, and CNC machining is an assembling procedure where parts/items are structured through machining instruments by computer inputs.

In this age, it is now considered as the dominant form of rapid prototyping.

Prototype CNC Machining is a fundamental and significant procedure for making prototype parts. Prototypes can have a dominant part of various cutoff points.

Generally, they go about as placeholder representations of the last part used to pass on and deliver visual information about how the last part glances and acts in different applied conditions.

However, on the off chance that these prototypes made to an exclusive expectation, they additionally may carry the capacity to be used to pitch the most recent market product to likely investors.

Such prototypes are crucial and need to be made through Prototype CNC Machining in regards to a precise output.

What is the process of Prototype CNC Machining?

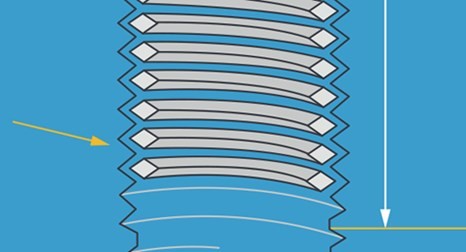

Prototype CNC Machine types include the standard mills with linear/rotary movement, lathes, and the majority of complex machines with multiple axes that can work multi-dimensionally to produce high-end and accurate parts/products which can be used for form, fit, and functional prototype testing.

The process of prototype CNC machining involves transferring a sophisticated program that has been processed through a 3D machining program to generate the required cutter paths to the CNC machine, which later runs an automated process to carry out the required “machining” procedures.

The Prototype CNC machine can also be programmed to repeat the same applied process in regards to multiple prototypes that can be replicated to the same specifications.

The results of this process pinpoint accuracy, consistency, and quality.

What are the reasons to use Prototype CNC Machining?

There are numerous reasons for using CNC Machining to produce a valid prototype, including enhanced production speed, high-quality parts, robust material options, and similarity to the final product.

- From sketch to prototype: One of the unique and significant advantages of CNC machining is the “CNC” element. Since it is a digital automated process that creates/designs parts from computer files, engineers believed that a machined prototype would closely match the digital 3D design, and this design is later used to create a final product.

- Consistency – Quality: There is a long walk from the perfect computers, but what we have now is a piece of perfect computer-controlled machinery that tends to function precisely as it’s supposed to. CNC machines can follow instructions within a fraction of a millimeter, and it is also the easiest way to guarantee consistency with an automated machine.

- The similarity to the final product: CNC machines are capable of creating prototypes similar to the required products. A majority of engineering metals are highly machinable and allows engineers to make prototypes from the same/similar materials they use for the final product.

How is CNC Machining beneficial for Prototyping?

The prototypes can be of many types based on the final product use. A few prototypes, in any case, can be utilized for something other than a visual representation.

Besides, contingent upon the phase of advancement, enterprises may require an engineering prototype or production prototype.

These prototypes simply seem as though the final product, yet work like it as well.

3D printing might be a vibrant alternative for looks-like prototypes, be that as it may, CNC machining is favored for these practical prototypes that require quality, mechanical solidness, and other fundamental mechanical/physical attributes.

What are the advantages of using Prototype CNC Machining?

In regards to prototypes, CNC Machining has several advantages:

- Create prototypes especially for the parts that eventually be produced by die-casting

- Produces prototypes produced using vigorous materials, in contrast to 3D printing

- The mechanical properties of CNC machined parts are incredibly similar to die-casting parts

- It can work with expensive material and even with common material like Aluminum

- CNC machined prototypes can be made with very good quality and fine surface finishes

- CNC machined parts can be anodized, coated, and beat blasted

- CNC machined prototypes have an excellent surface quality to fill in as a final prototype for introduction

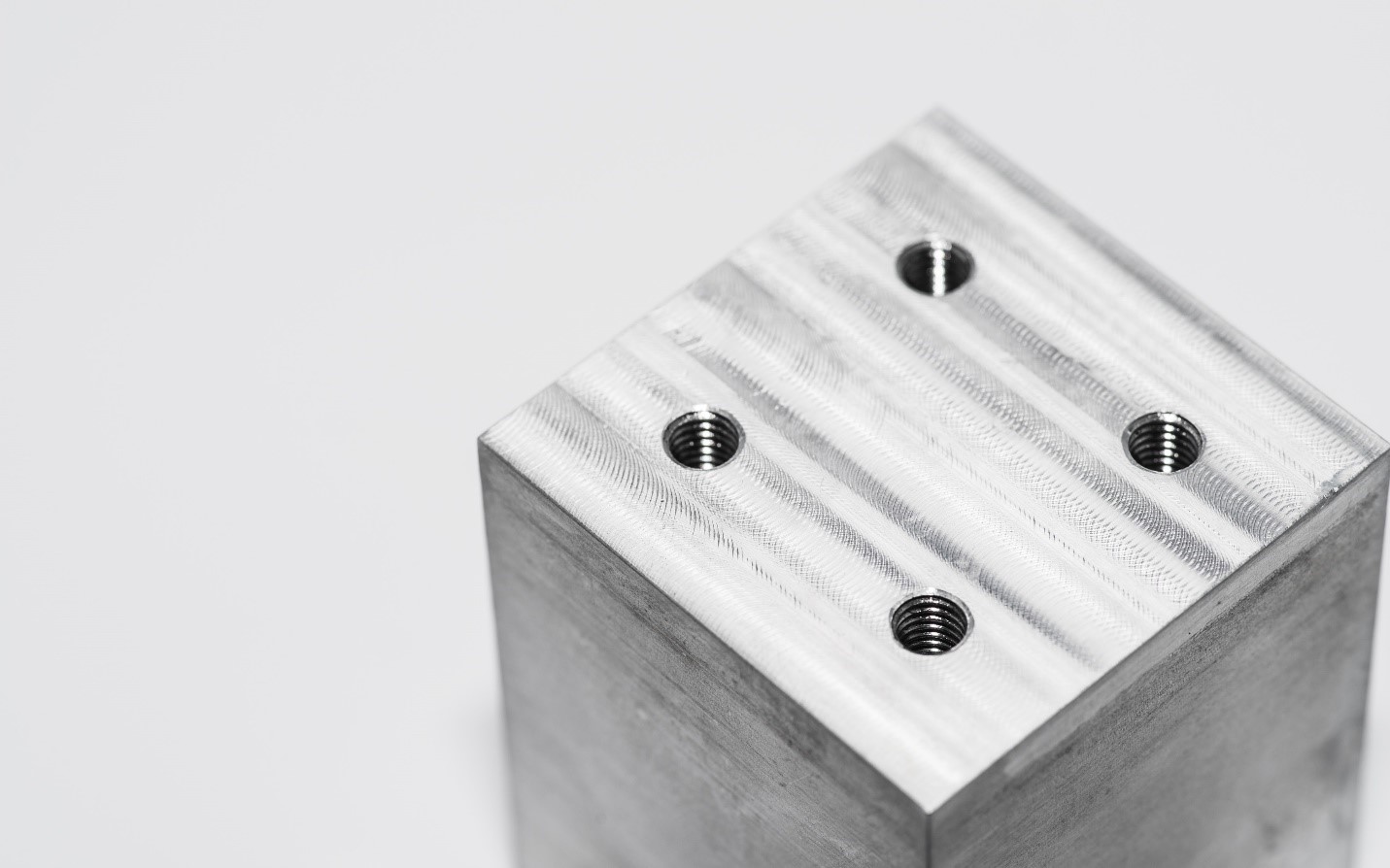

What are the Milled parts in Prototype CNC Machining?

Prototype CNC milling is preferred in regards to creating complex 3D shapes/prototypes, apply a machined surface or features to parts made from metals.

The advantage of multi-axis CNC milling machines makes CNC milling process versatile, accurate, and repeatable;

To create/manufacturing different and unique parts/prototypes features intricate geometrical designs.

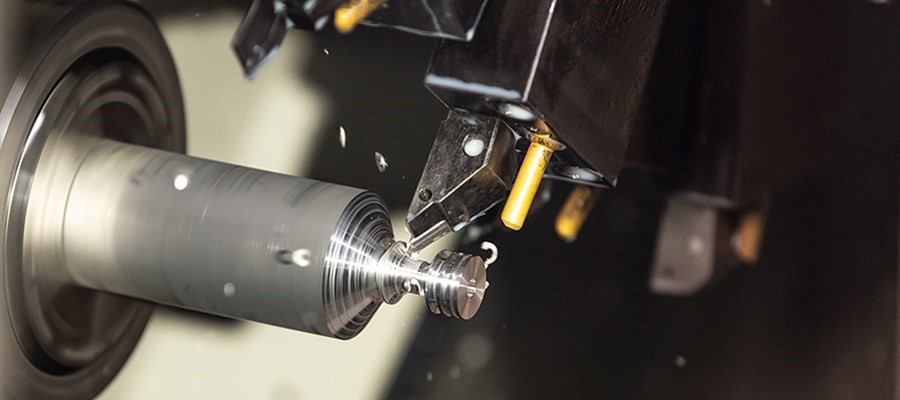

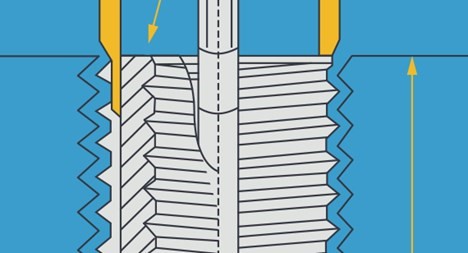

What are the Turned parts in Prototype CNC Machining?

Prototype CNC lathes enable high-speed turning of metals like Aluminum from bar/block materials.

This turning process additionally permits the creation of complex external/internal geometries, just as producing a wide range of strings.

Be that as it may, for any round molded part, including shafts, circles, worms, prototype CNC turning is an increasingly productive and exact strategy contrasted compared with prototype CNC milling.

What are the applications of Prototype CNC Machining?

- Prototype Designs: Prototype CNC Machining is commonly used by originators as a technique for collecting early-/late-stage prototypes with a short time recovery option. CNC machining is the best way to create a concept model and function prototype to verify the design.

- Rapid prototyping: Prototype CNC machining is a favored choice to bring new plan life among the other quick prototyping strategies.

- Mold Making: Fast prototype CNC machines empower us to make high-exactness aluminum designs, form pits, shape base, lifter, and other form parts for the time being.

- Aerospace: Prototype CNC machining has an integral part in aerospace manufacturing. That’s down to a high-precision of CNC machines, making the process best for critical parts safety.

Aerospace CNC machinable parts include; Prototype engine parts/components, Fuel panels, Landing gear parts/components, Engine mounts

- Automotive: Prototype CNC machining is the most famous technique to make idea vehicles just as working test parts.

Moreover, it’s particularly valuable for custom automotive parts.

- Medical: The machinability of numerous evaluations of Aluminum and Stainless steel makes prototype CNC machining a generally utilized procedure in medicine, with the procedure used to make medical gadgets and surgical instruments.

- Consumer Products: in-house products regularly contain machined parts, while things, like fenced-in areas and apparatuses, are reasonable for the prototype CNC machining process.

Things, for example, PC casting, connectors, and attachments are made through this.

How Prototype CNC Machining design precision machining parts?

Aside from standard and conventional prototype CNC models, prototype CNC machining also offers high-quality precision CNC machining prototypes.

Generally, it is a core property of rapid prototyping via CNC machining to deliver high-speed, high precision, and exceptional quality part/product manufacturing solutions.

For instance, you take a billet/square of material like Aluminum and remove it with an assortment arrangement of apparatuses and boring tools.

Furthermore, removing unrequired or raw material to make CNC machined part/prototype.

Following are some advantages of this precision prototype CNC machining:

- High-speed and repeatable for a low-volume designing/manufacturing

- CNC prototypes effectively convey exact and high-resistance particulars

- The vast majority of production and rapid prototype designing/manufacturing materials

- High surface finishing through rapid prototype machining

What are the materials & finishes required by the Prototype CNC Machining?

The most common materials used for prototype CNC machining are Aluminum, Steel, Stainless Steel, Magnesium, Titanium, Zinc, Brass, Bronze, and Copper.

Aluminum is considered the best in the majority of cases in which prototypes are of a die-casting part.

Furthermore, they were also the most common materials for production parts.

Our industry uses advanced equipment to offer high-quality CNC prototypes to our clients.

Here we gather the top accessible materials chosen by the majority of our customers for their CNC prototyping.

- Aluminum: A380, ADC12

- Aluminum-Silicon: AlSi12

- Aluminum-Silicon-Copper: AlSi9Cu

Prototype CNC Machining can produce parts/designs with tight tolerances (up to ± 0.025 mm).

Because of the subtractive idea of CNC, minor device imprints can be noticeable on a surface after machining.

A larger part of post-preparing and completing techniques are applied by their need with respect to improving surface roughness, visual properties, and wear resistance of CNC machined prototype.

- As CNC Machined Finish

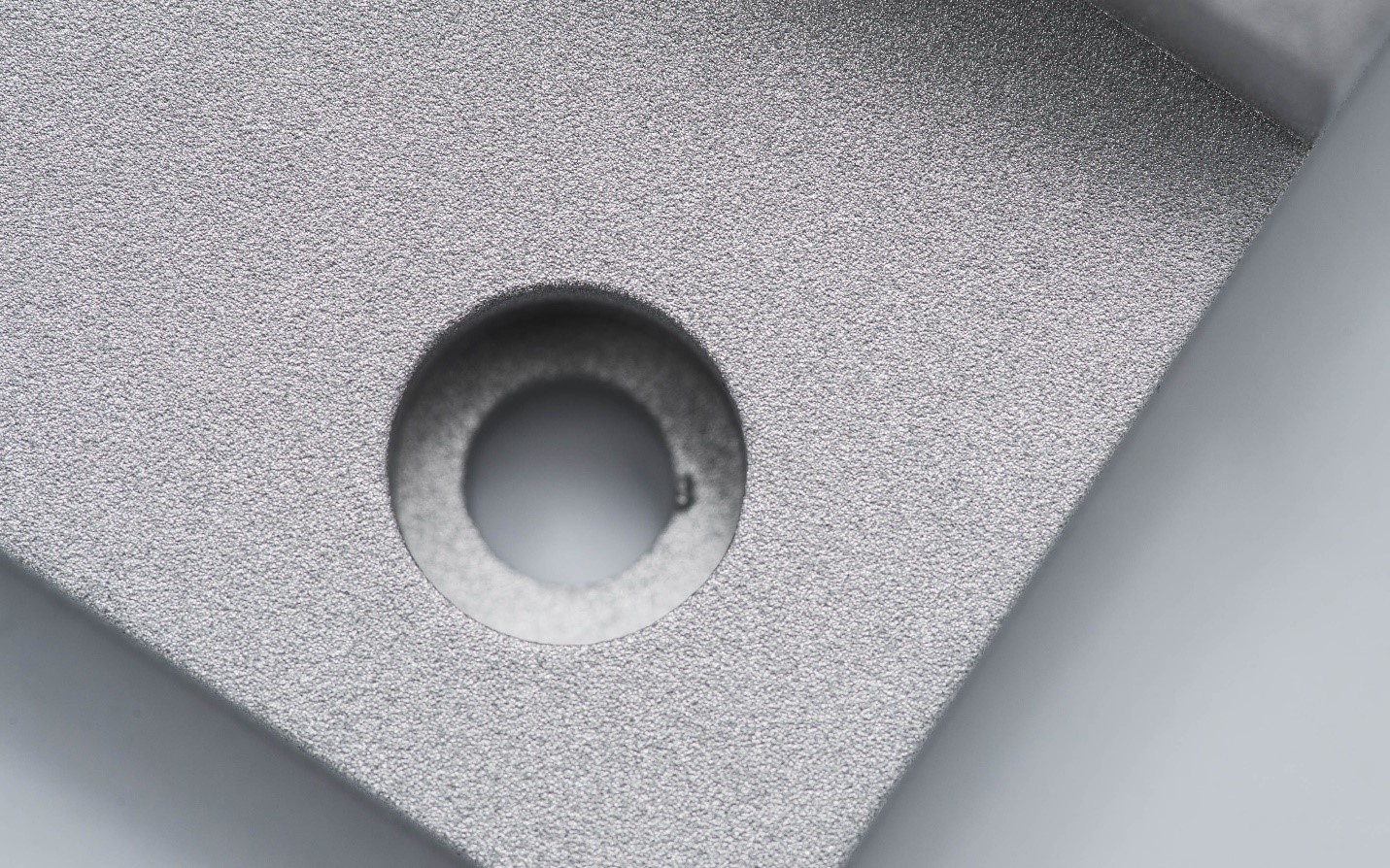

- Bead Blasting

- Anodizing (Type II & III)

- Powder Coating

How to determine which surface finish is required by which CNC machined prototype?

Five rules of thumb are used in regards to selecting the right surface finish for a particular CNC machined product.

- Use “As Machined Finish” for the prototypes/parts with tight tolerances, where aesthetics is not a problem.

- Use “Bead Blasting” for the prototypes/parts with a matte uniform surface finish, as well as where dimensional tolerances are not a core/key concern.

- Use “Anodizing Type-II” on the off chance that it’s required to include a thin, stylishly satisfying, and defensive layer to the Aluminum parts/prototypes.

- Use “Anodizing Type-III” in applicants/prototypes related to engineering, where high wear-resistance and surface hardness is essential properties.

- Use “Powder Coating” for prototypes where high impact strength is liked and required or to complete prototypes that can’t be anodized.

Why prefer Prototype CNC Machining?

There are five base reasons for preferring Prototype CNC machining over other methods like 3D printing and are described below:

Our industry inclines toward mechanized design analysis that point-out attention to machine features before the design is sent for assembling and spare you costs and lessen the item improvement process duration.

- Design for Manufacturability Feedback: Prototype CNC machining enables us to analyze the 3D CAT (computer soft-copy design) product/prototype geometry to identify complicated features to the machine as tall, thin walls, or holes that can’t be threaded.

- Safe & Sound: Eliminate the risk of false, unbalanced, or impossible design manufacturing by choosing the perfect and functional prototype through CNC machining.

- Infinite Capacity: Eliminate the downtime spent waiting for the successful parts to be manufacture by first prototyping the product and, after an unbeaten run, manufacturing the authentic products fast.

- Material Selection: Prototype CNC Machining offers metals that are unique and can be processed through engineering and production prototyping in regards to obtaining a functional prototype.

Can you get tight tolerance parts from Prototype CNC Machining?

Yes! With high precision prototype CNC machines, our industry can catch ultra-tight tolerance for prototype machining & production.

Furthermore, the parts are made accordingly to the standard customers’ specifications.

In case, the 3D design is not available, you always have the option to provide a 2D design.

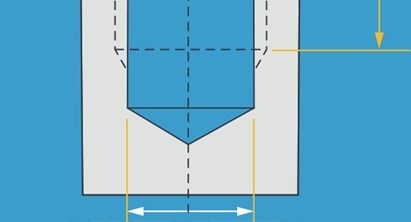

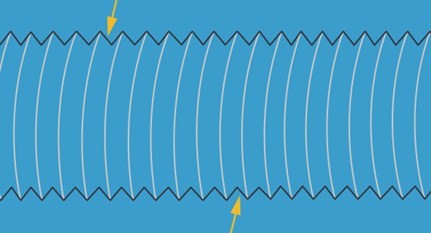

What are the threaded options for Prototype CNC Machining?

The threaded features can be easily added in machined parts/prototypes, including key/coil inserts.

These can be indicated inside your intelligent quote when a quote is returned. The 3D display shows the possible thread types for each feature.

Additionally, different strings/threads (where possible) or no strings/threads can be picked on a feature-by-feature premise.

There can be four types of threaded options:

- Standard Holes

- Coil Inserts

- Key Inserts

- OD Threads

What benefits Prototype CNC Machining offers?

Prototype CNC Machining is perfect for meeting a majority of development needs.

The following are the benefits of using prototype CNC machining:

- Fast removal of high amounts of metal materials

- Highly accurate and repeatable

- Suitable for the majority of substrates

- Scalable volumes from 1 to 100,000

- Low investment and preparation tooling costs

- Economical

- Quick turnaround