WHY CHOOSE SUNRISE METAL

Sunrise Metal, a China-based aluminium die casting manufacturer, proudly offers high-quality products in die casting manufacturing industry. From tooling design to casting parts manufacturing, finishing, and packaging, we provide comprehensive and cost-effective solutions for all your aluminum die casting needs.

- 1-Stop precision aluminum die casting solution provider

- 10+ years of experience, 4 facilities & 182 employees

- ISO 9001 & ISO 13485 & IATF 16949 certified

With turnkey solutions, a team of experts, and a commitment to delivering superior-quality products and services, we help you save costs and run your projects more smoothly. Contact us with your next project.

ONE STOP DIE CASTING SERVICE

We offer a wide range of services other than just die casting. Our one-stop service Starts from rapid prototyping to high quality surface finishing. We help you get the final product with ease and here in one place.

- Prototyping for Die Casting

- Die Casting Tooling

- Aluminium Die Casting

- Secondary CNC Machining

- Die Cast Surface Finishings

Prototyping for Die Casting

Full Service: prototyping tooling & 3D printing & die cast prototyping & CNC prototyping service in-house.

Wide range of materials: Plastic: ABS, POM, PMMA, Nylon, etc. Metal: Aluminum, Zinc, Copper, Stainless Steel, etc.

Experience the convenience of our versatile multi-axis machines, tailored to fulfill your low to medium volume demands. Accelerate your product development with fast-turn prototypes, ensuring swift progress and efficient production.

Die Casting Tooling

Seamless Control for Faster Results: Our in-house tooling capabilities streamline the entire die casting process. We handle design, fabrication, and maintenance under one roof, eliminating delays and miscommunications common with outsourced tooling.

Proactive Problem-Solving: Our expert mold engineers go beyond just reviewing your drawings. Cutting-edge mold flow analysis proactively identifies potential issues, saving you time and money during production.

Aluminium Die Casting

Your Partner in Precision: At Sunrise Metal, we understand that precision aluminum die casting is critical to your product’s success. Our 23+ years of experience ensure meticulous attention to detail and tolerances your project demands.

Problem-Solvers, Not Just Manufacturers: Tap into our seasoned engineering team for support throughout your project. We offer design collaboration, proactive solutions, and a commitment to finding the optimal path forward.

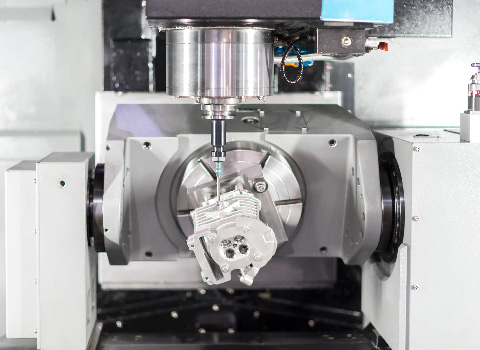

Secondary CNC Machining

Expand Capabilities: We offer more than just die casting. Tap into our comprehensive service, including precision CNC machining for intricate designs and demanding tolerances.

Accuracy: Our high-tech equipment and expertise ensure exceptional precision, achieving tolerances down to ±0.0015mm (JIS B6336).

Complex Projects: We excel in high-mix, low to medium-volume projects where flexibility and customization are critical.

Die Cast Surface Finishings

Matte Finish In-House: Get a consistent matte finish for your die-casting and machined parts with our cleaning and shot blasting services.

Protective and Decorative Finishes: Choose from outsourced anodizing (for corrosion resistance), powder coating & liquid painting (for durability and color), and silk screening, pad screening, & laser carving (for branding and identification).

Convenience: Streamline your process by leveraging our complete range of finishing solutions.

DIE CASTING PRODUCTION & MEASURING EQUIPMENT

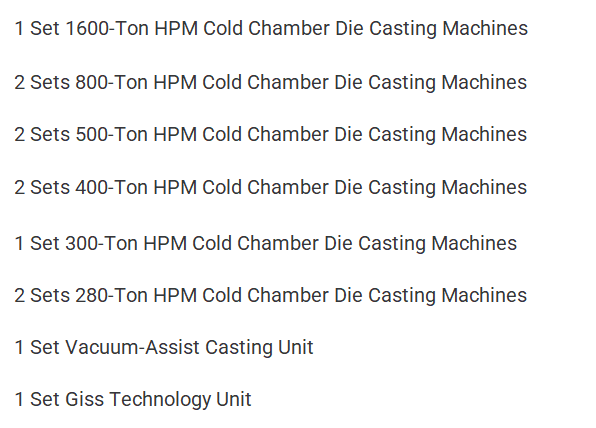

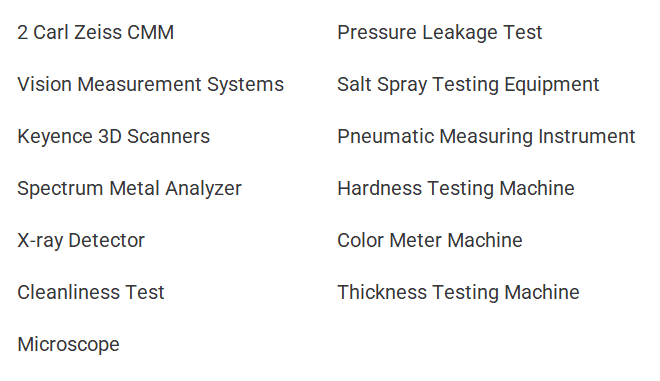

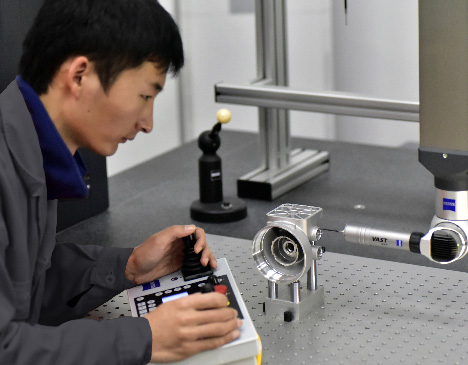

Our equipment includes die casting machines (280T to 1600T), GISS Semi-solid Die Casting, Vacuum Die Casting, Mold Temperature Controllers, Makino CNC Machines, Carl Zeiss CMMs, Vision Measurement Systems, and Keyence 3D Scanners. With these advanced tools, we tailor precision solutions to each customer’s needs , ensuring quality assurance.

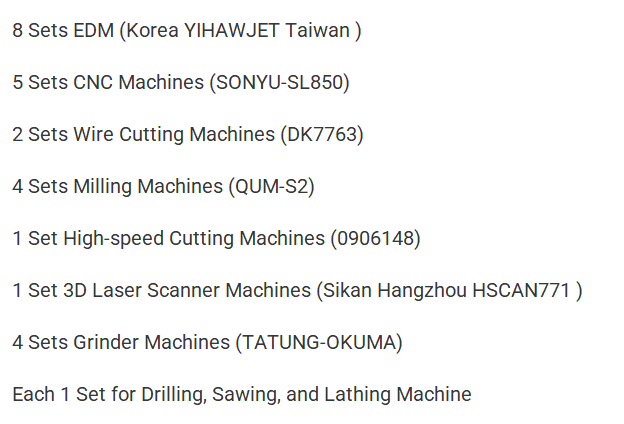

- Tooling & Die Equipment

- Die Casting Eqipment

- CNC Machining Equipment

- Quality Assurance Equipment

DIE CAST PARTS ENGINEERING SUPPORT

Sunrise’s engineers use computer-aided engineering (CAE) and with their rich technical experience, they can optimize the design for rapid prototypes, die-casting tooling, and casting parts. Moreover, our engineers are professional in the application of CAE including:

- Pro/Engineer and Pro/Manufacture to ensure feasibility for your products’ design, tool design, and production.

- Proficient at working with CAD/CAM files from the virtual system

- Simulation flow analysis to predict how the mold will fill, solidify, and cool-reducing the risk of defective die-casting parts.

- Valued engineering solutions to help reduce costs throughout the manufacturing process

DIE CASTINGS QUALITY ASSURANCE

PROCESS CONTROL FOR DIE CAST COMPONENTS

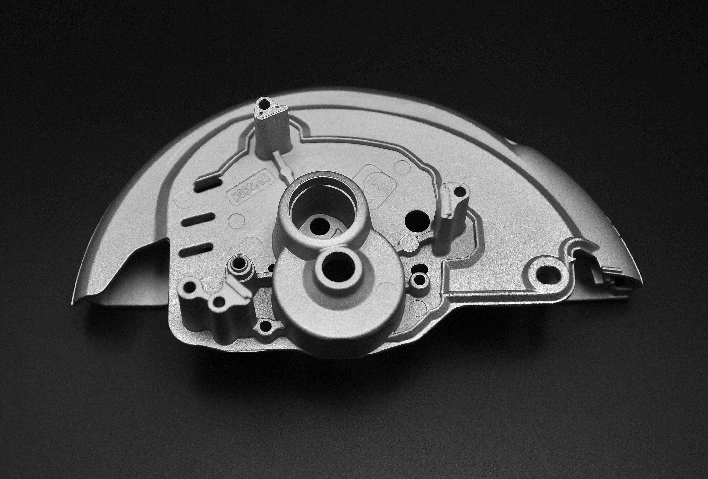

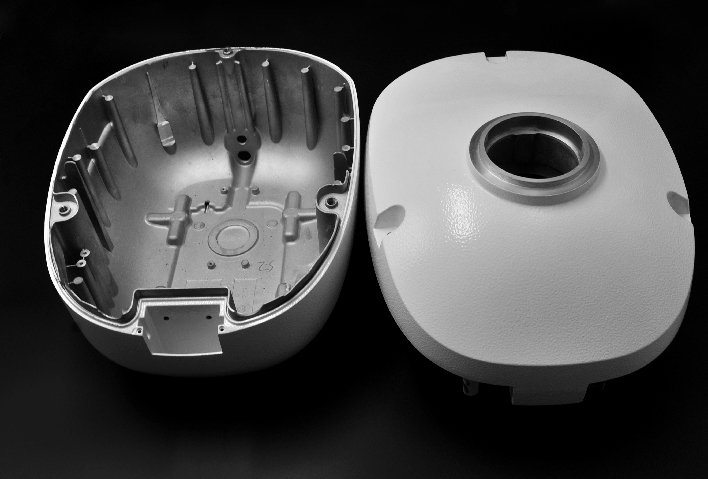

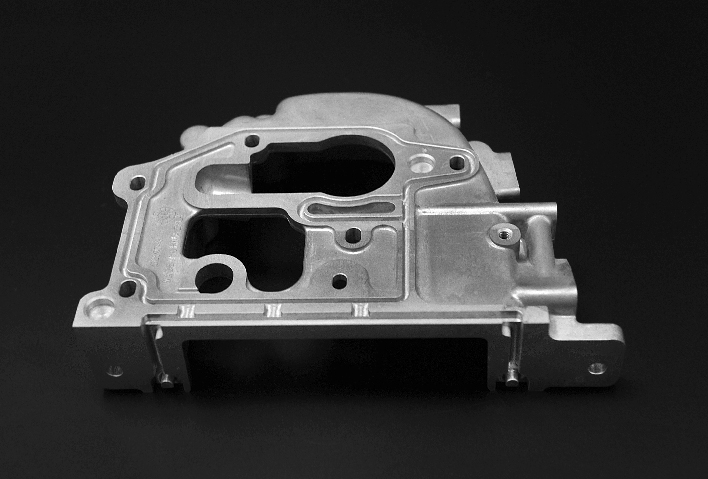

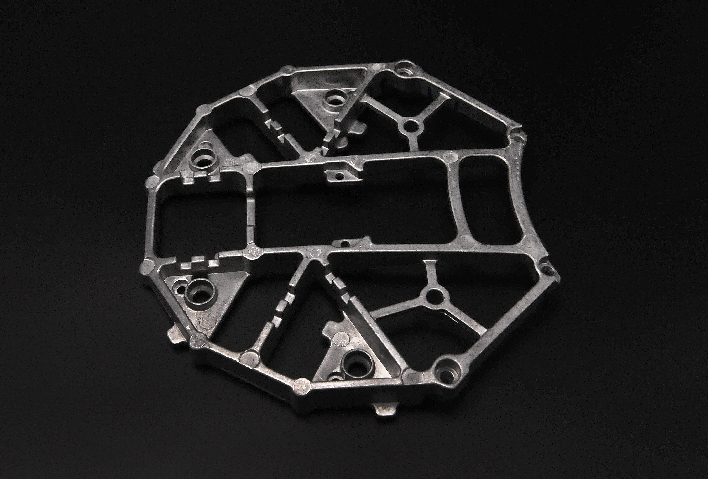

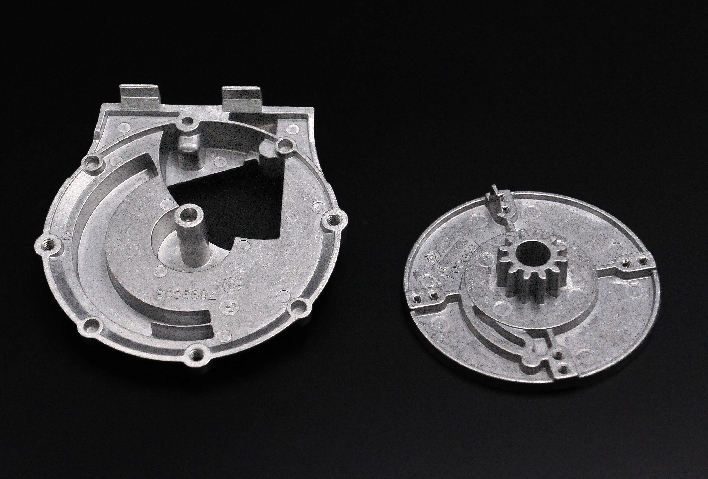

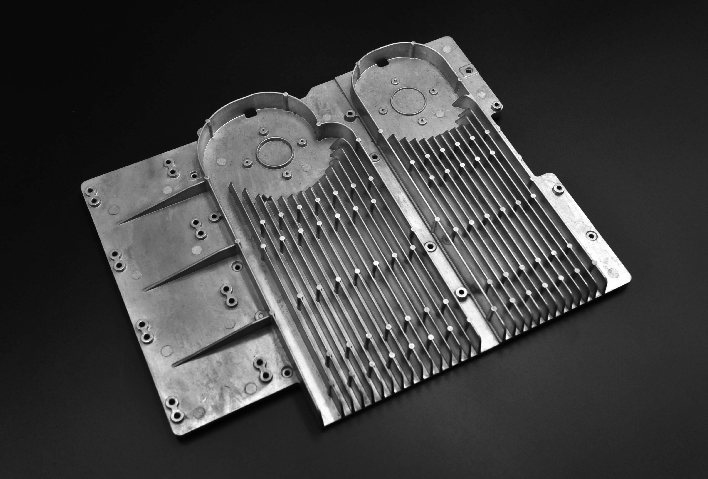

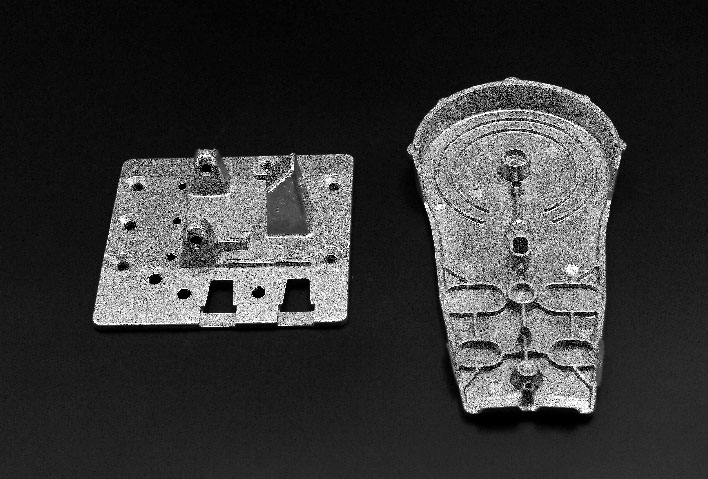

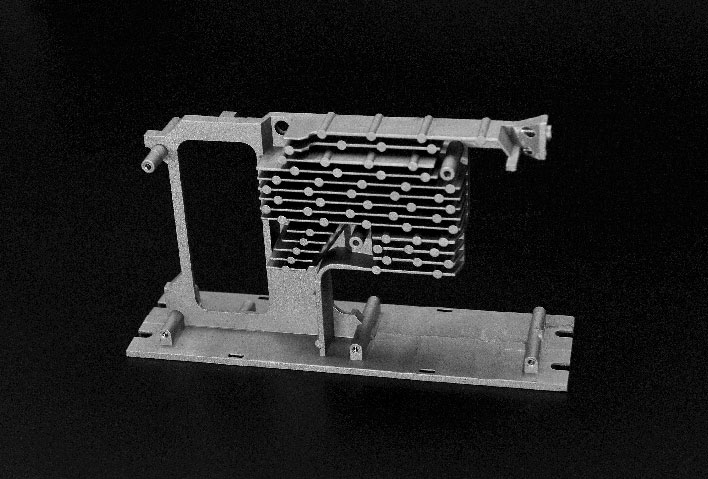

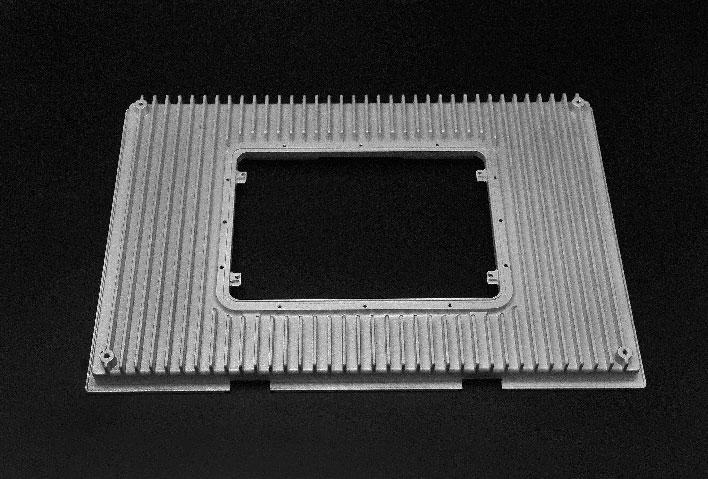

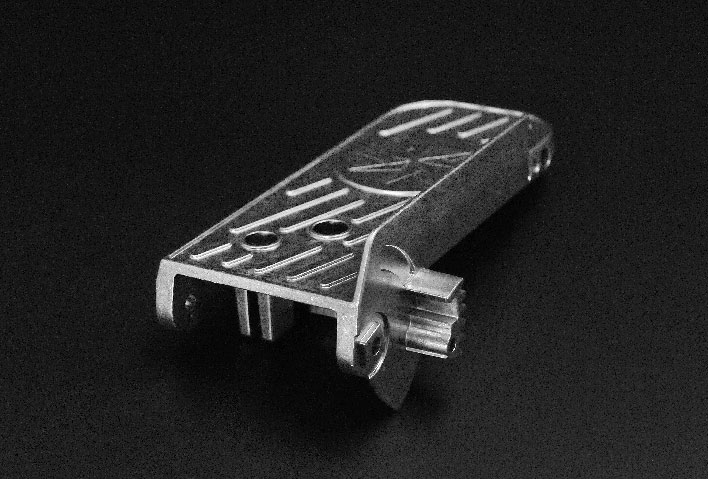

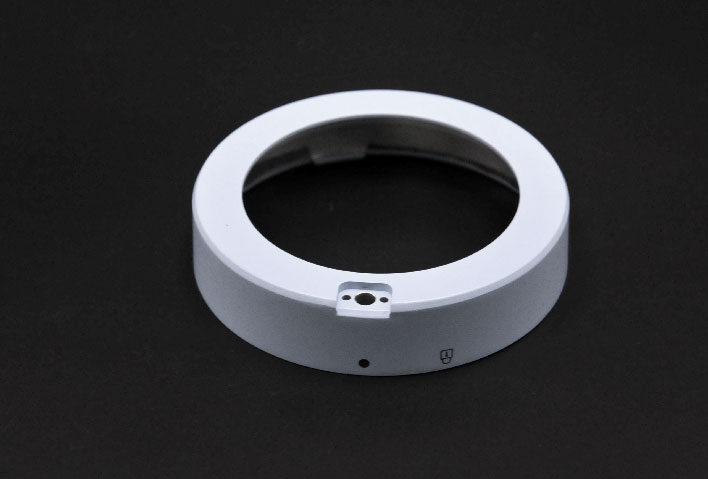

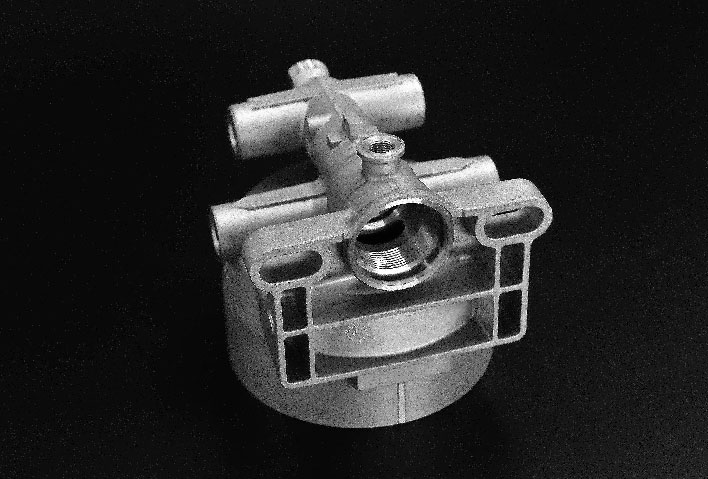

DIE CASTING PRODUCTS GALLEY

- Medical Device Application High Strength, Light Weight

- Lawnmower Machine Application Durability & Precision

- Marine Application Strong Corrosion Protection

- Automotive Engine Application High Strength & Porosity Control

- Medical Equipment Industry High Strength & Durability

- Power Tools Application Precision & Durability

- Communication Industry Powder Coated Treatment

- Medical Equipment Component Efficient Thermal Conductivity

- Marine Application Strength & Durability

- Medical Device Application High Strength Effective Heat Dissipation

- Marine Electronic Panel Precision & High Flatness

- Marine Industry Strength & Wear Resistant

- Medical Operating Light System Durability & Heat Resistance

- Marine Application Durability & Corrosion Resistance

- Truck Filtration System Tight Tolerances Effectively Preventing Leaks

LISTEN TO THE VOICES OF OUR CLIENTS

I am very appreciated. The BK products that you folks support are on an upswing, so hopefully, 2020 will be prosperous for both companies. I also want to thank you for your support in cost reductions and pulling in deliveries. Much appreciated.

Sunrise never let me down, whatever the new projects or current ongoing parts. They do have rich experience and this great help. I like their perfect DFM, really fast, and on-time delivery.

Thank you, the quality is very well. I wish next year will be successful so that we can do more business with you.

PROUD ALUMINUM DIE CASTING SUPPLIER OF

SUNRISE METAL FAQ GUIDE

Looking for the ideal solution for high or low to medium volume production of your products? Look no further than an Aluminum Die Casting Supplier. With over a decade of experience, Sunrise Metal in China excels in aluminum die casting, offering fast and reliable solutions for your project needs.

Q: Can you design my parts and execute mold flow analysis for aluminum die casting production?

A: Yes, we have experienced designers and the necessary hardware required to design parts for you. Additionally, we can conduct effective simulations for mold flow analysis in advance. Our talented engineers can design your parts with a high degree of accuracy and optimize them for easier production, cutting down on costs.

Q: Can you provide PPAP support?

A: Absolutely. The Production Part Approval Process (PPAP) is an essential part of various industries, and we’ll guide you through the entire approval process, ensuring you don’t have to worry about it.

Q: How does Sunrise Metal control the quality of the production process?

A: Sunrise Metal, as professional aluminum die casting factory, we maintain a superior quality management system certified by ISO 9001, ISO 13485, and IATF 16949 standards. We uphold optimum quality control in all stages of production, ensuring maximum quality for the parts we produce.

Q: How do you ensure part traceability?

A: Every production batch is assigned a Batch Control Card, meticulously recording essential details. Additionally, each part receives a unique identification through labeling, printing, or laser etching, ensuring comprehensive traceability throughout the production process.

Q: Is Sunrise Metal a continually improved company?

A: Yes, our company is committed to continuous improvement. With over a decade in the die casting business, we’re constantly enhancing our technical capabilities, optimizing production practices, and investing in innovation to provide you with the best possible experience and solutions.