ALUMINUM DIE CASTING METALS

Aluminum is one of the most popular choices as a die casting metal. Manufacturers can cost-effectively produce intricate parts with a shorter lead time. Here we have briefly discussed the characteristics, advantages, types, and applications of aluminum die casting metals.

Aluminum Alloy Characteristics

Aluminum metal alloys have some unique characteristics that distinguish them from other die casting alloys. Some key characteristics of aluminum alloy are:

- Very lightweight

- Great corrosion resistance

- Superior electrical and thermal conductivity

- Can withstand high operating temperatures

- Excellent strength-to-weight ratio with good stiffness

- Great EMI/RFI shielding properties

- Wide range of surface finishing options

Advantages of Aluminum Die Casting

Aluminum die casting offers multitudes of benefits over other metalworking techniques. Some of the main advantages of aluminum die casting are as follows:

- High production efficiency

- Produce parts with Intricate details

- Achieve variable wall thickness

- High precision

- Superior repeatability

- Material can be recycled

- Great dimensional stability

All these perks combined, make aluminum die casting a cost-effective manufacturing process. And, the cost is unarguably one of the key deciding factors for any project.

Common Die Casting Aluminum Alloys

Various forms of aluminum metal alloys are specifically used for die casting. Some of the common die-casting aluminum alloys include,

- A360

- A380 (ADC10)

- A383 (ADC12)

- A304 (K-Alloy)

- B390

- A413

- AlSi9Cu

- AlSi10, etc.

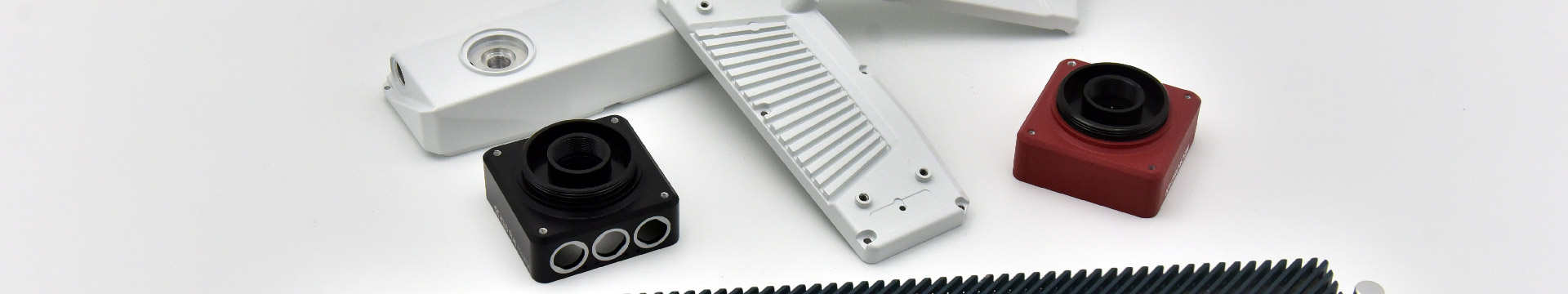

Aluminum Die Casting Metal Applications

Here are some common applications for aluminum casting:

Automotive

Lighter components can greatly increase the fuel efficiency of vehicles. That’s why the automotive industries use aluminum diecast parts to reduce the weight of the vehicle while meeting the structural requirements.

Telecommunication

Aluminum enclosures are widely used in the telecommunication sector. It is commonly used as RF filter housing for its excellent shielding and heat dissipation properties.

Consumer Electronics

Aluminum is the material of choice for handheld or portable electronic devices such as laptops, smartphones, cameras, etc. The lightweight, durability, and aesthetics of aluminum castings have made them very popular to end users.

Industrial Equipment

The superior thermal and electrical conductivity of aluminum die casting metals makes them ideal for industrial applications as well. Diecast aluminum parts can withstand high operating temperatures. They are commonly used as equipment housing and heatsinks.

Aluminum Alloys That We Offer

Sunrise Metal offers a wide range of aluminum alloys to choose from. To ensure the best experience for our customers, we mostly use ADC10, ADC12, AlSi9Cu, AlSi10, K-Alloy, etc. aluminum alloys for die casting. However, you can also request special aluminum die casting alloys for your project. You can get a quote from us for your project as well, we usually reply within 24 hours.

Which Die Cast Metal is Best for Your Project?

For most of the common applications, aluminum alloy die casting may be more desirable provided that it meets your project requirements. The advantages of aluminum die casting can easily outweigh its limitations. Especially when dealing with a large volume of parts.

However, if you are dealing with smaller components with high strength requirements, then Zinc may be more suitable. Moreover, if you need your parts to be as light as possible, without the cost being a major factor, then Magnesium could be an alternative to aluminum alloys.